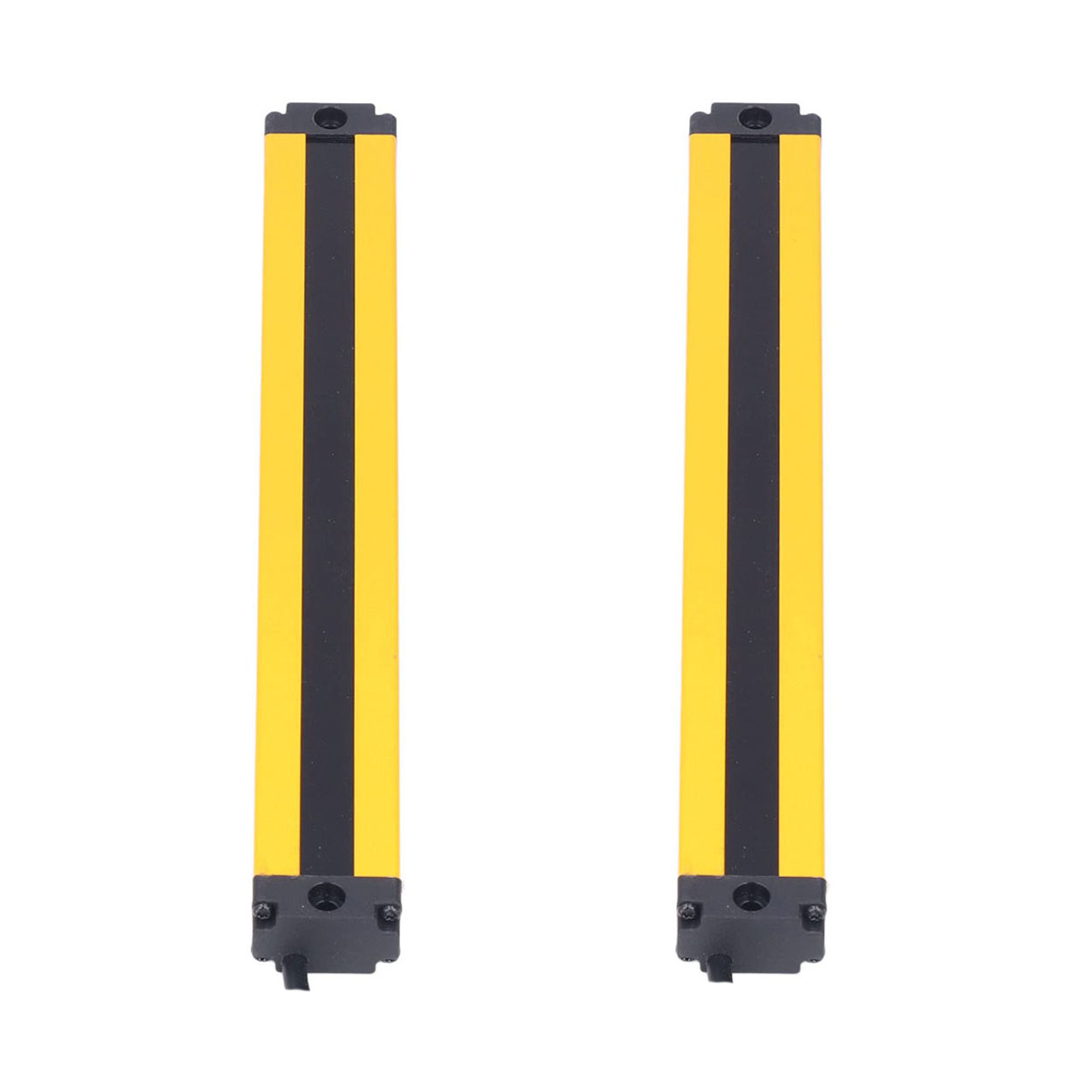

China Magnetic Light Guards Safety Laser Sensor for Machine

Enhancing Industrial Safety with Advanced Laser Sensor Technology

Safety laser sensors are paramount for protecting fingers and hands, ensuring secure machine access monitoring. These safety light curtains deliver high availability, significantly reducing machine and plant downtimes. Available in two distinct variants—Base and Standard-Muting—they cater to both standard and intricate applications, including muting scenarios. Efficient and ergonomic monitoring of hazardous operation points and machine access is crucial, particularly in production environments necessitating frequent interventions. Safety laser sensors offer a highly reliable and user-friendly solution for these critical applications.

Maintaining detection area sensors involves regular inspections and cleaning to ensure optimal functionality:

- Regular Cleaning: Keep the sensor lenses and surfaces free from dust, dirt, and obstructions to maintain accurate detection.

- Routine Inspections: Periodically check the alignment and condition of the emitter and receiver elements. Look for signs of wear, corrosion, or damage.

- Lubrication: Apply appropriate lubricants to moving parts, if applicable, to reduce friction and prevent wear.

- Firmware Updates: If the sensors are equipped with firmware, ensure they are updated regularly to benefit from performance improvements and bug fixes.

Overview of Safety Laser Sensors

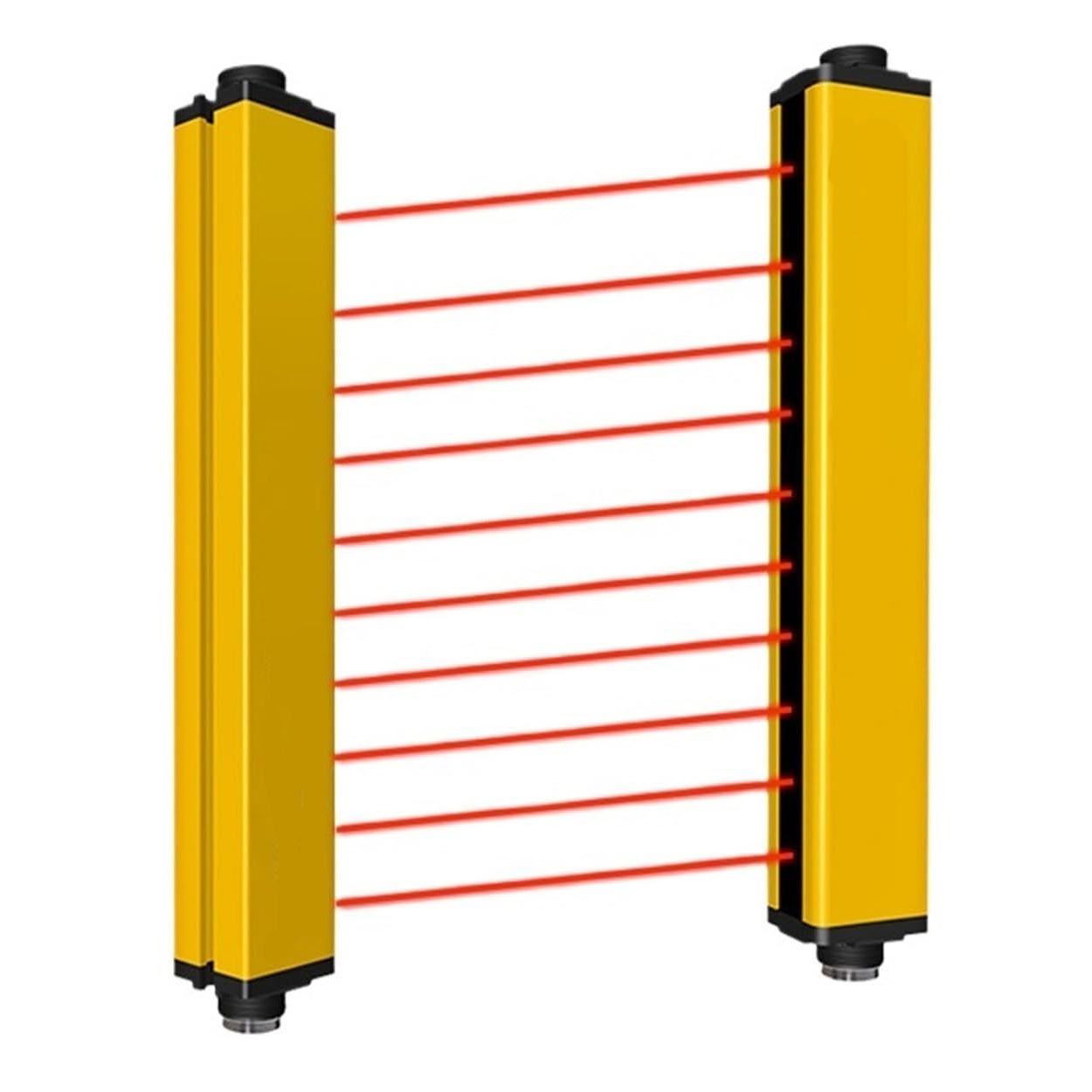

Safety laser sensors are engineered to safeguard personnel and machinery by establishing a protective sensing screen around machine access points and perimeters. These sensors utilize self-contained emitters and receivers to create a non-contact guarding system, effectively preventing accidents and minimizing downtime.

Key Features of Safety Light Curtains

- Configuration Without Software: Simplifies setup and reduces implementation time.

- Zero Dead Zone: Ensures uninterrupted protection without any blind spots.

- Adjustable Protective Field Heights: Ranges from 300 mm to 2100 mm, accommodating various operational needs.

Benefits of Implementing Safety Light Curtains

Safety light curtains offer numerous advantages that enhance both safety and operational efficiency within industrial settings.

Installation and Integration

- Easy and Fast Installation: Eliminates the need for extensive programming, allowing for quick deployment.

- Space-Saving Design: Facilitates flexible integration into existing machinery without occupying excessive space.

- Seamless Replacement: Requires no design changes, reducing the number of necessary accessories and simplifying maintenance.

Operational Efficiency

- Reduced Downtime: Fast on-site diagnostics help identify and resolve issues promptly, minimizing production interruptions.

- Versatile Application: Suitable for a wide range of applications, from high-risk environments to more economical settings preventing minor injuries.

Comparative Analysis of Base and Standard-Muting Variants

Feature Base Variant Standard-Muting Variant Application Scope Standard applications Complex and muting applications Configuration Requirements No software needed Enhanced configuration options Field Heights Up to 2100 mm Up to 2100 mm with additional muting capabilities Installation Complexity Simplified for standard setups Designed for intricate setups Cost Efficiency Economical for basic needs Cost-effective for advanced requirements

Applications in Industrial Environments

Safety laser sensors are integral to various industrial applications, ensuring both operator safety and machinery integrity. They are particularly effective in environments requiring frequent machine access and intervention, such as assembly lines and manufacturing plants.

High-Risk Applications

In settings with elevated risk levels, safety light curtains are equipped with microprocessor-controlled and self-checking designs. These advanced features provide robust protection, preventing severe injuries and ensuring compliance with stringent safety standards.

Low-Risk Applications

For environments where the risk is comparatively lower, more economical safety light curtains are available. These solutions are effective in preventing minor injuries, such as cuts or bruises, thereby enhancing overall workplace safety without significant investment.

Conclusion

Safety laser sensors, particularly safety light curtains, are essential components in modern industrial safety systems. Their ability to provide reliable, non-contact machine guarding ensures the protection of personnel and machinery alike. With features like easy installation, zero dead zones, and versatile application options, these sensors offer a comprehensive solution for maintaining safe and efficient production environments. As industries continue to evolve, the integration of advanced safety laser sensors will remain a critical factor in achieving operational excellence and safeguarding human resources.

Why Choose Us

Safe Light Guard

Our Safety Light Curtains represent a significant advancement in protective safety technology. With their robust construction, fast response times, and compliance with international safety standards, these sensors provide a critical safety function in various industrial settings. By integrating these systems, businesses can enhance operational safety and protect their most valuable assets— their people and their machinery.

Industrial Safety Upgrade

Incorporating safety light curtain sensors into industrial operations not only complies with legal safety standards but also promotes a culture of safety and responsibility. This technology is a cornerstone in modern industrial safety practices, playing a pivotal role in preventing accidents and enhancing overall workplace safety.

Frequently Asked Question

Know what you want to know about the safety laser sensors.

- Industries with automated machinery, such as automotive assembly, packaging, metal fabrication, and electronics manufacturing, gain significant value. In these settings, safety laser sensors and light curtains can help protect operators during processes that involve pressing, cutting, or handling heavy and fast-moving equipment.

Zero dead zones ensure there are no unprotected gaps along the full length of the detection field. This feature provides continuous coverage from the top to the bottom of the sensor’s protective area, offering uniform safety and enabling closer, more precise placement near the hazardous zone.

- By preventing accidental injuries and damage to the equipment, safety laser sensors reduce the frequency of emergency stops and repairs. In addition, their built-in diagnostics allow for rapid troubleshooting, helping technicians quickly identify and resolve issues, thus minimizing downtime and associated operational costs.

- They are certified with CE, FCC, and ROHS standards, ensuring compliance with international safety and environmental regulations.

- Safety laser sensors create a virtual “curtain” of light beams emitted and received by integrated, self-contained units. If a hand, finger, or object interrupts this invisible field, the sensor signals the machine’s control system to stop or slow movement, thereby preventing direct contact between an operator and hazardous parts.

- Yes. Many modern safety laser sensors and light curtains are designed for plug-and-play installation, eliminating the need for complex programming. Configuration can typically be done through simple wiring and basic parameter selection, allowing for quick deployment and easy maintenance.

- These sensors provide secure, non-contact protection that doesn’t require mechanical barriers like guards or cages. Operators can easily approach the machine to perform loading, unloading, or adjustments without removing physical barriers. This streamlined access reduces strain and promotes a more ergonomic, user-friendly work environment.

- The ultra-thin design and versatile mounting options facilitate straightforward installation. Their compact profile allows them to be seamlessly integrated into existing machinery with minimal modifications, ensuring a hassle-free setup process.

Safety Curtain Sensors, Photoelectric Sensors, Proximity Sensors, Mesauring Sesnors, LED Tower Light