Inductive Industrial Safety Sensor Machine Light Curtains

Overview of Inductive Industrial Safety Sensor Machine Light Curtains

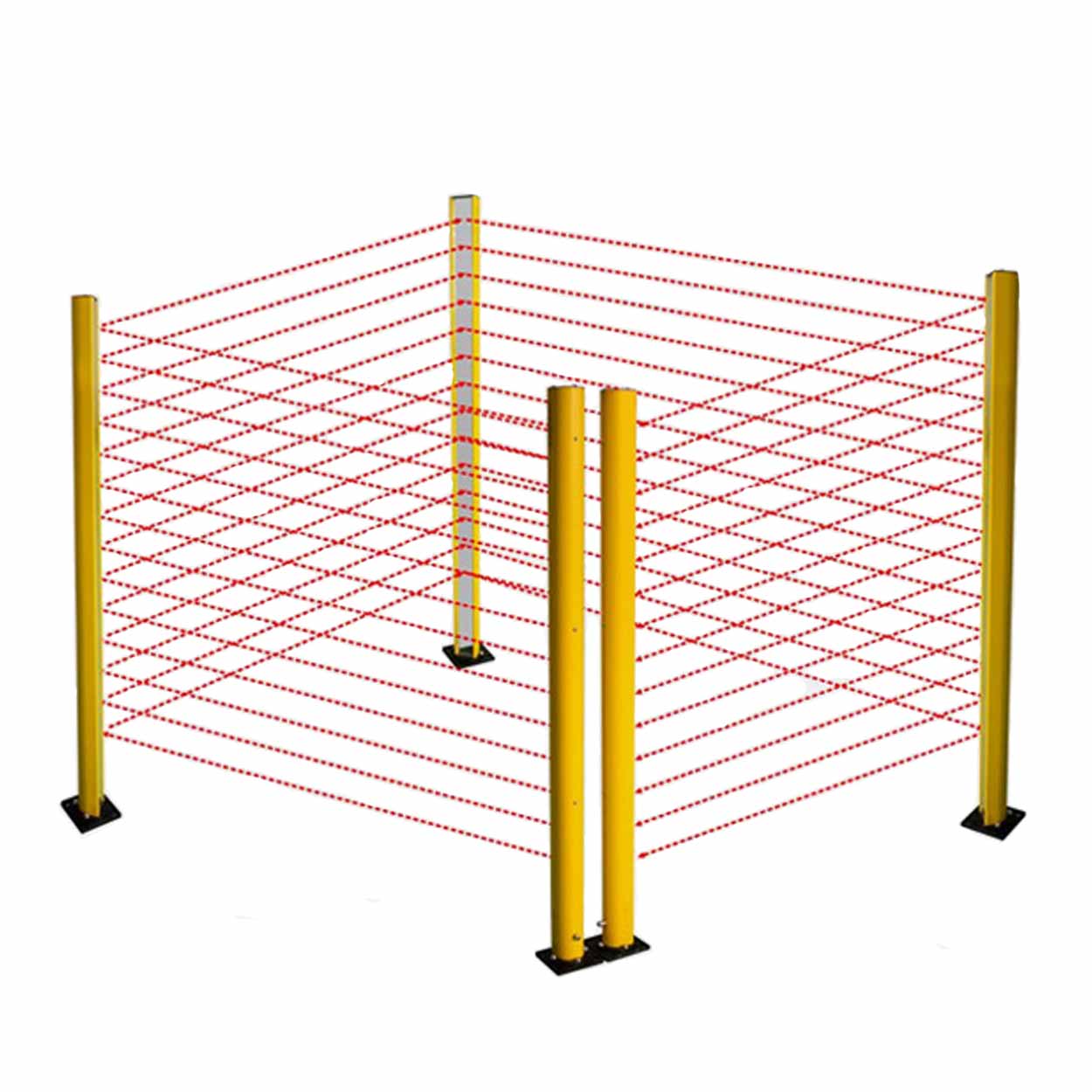

The inductive industrial safety sensor machine light curtains utilize advanced retro-reflective mirror technology to create a robust network of infrared protection adaptable to various industrial environments. Enhanced with surface-mount technology, these light curtains exhibit superior shock resistance, ensuring consistent performance even under significant vibration. They offer flexible protection options, ranging from single to quadruple sides, with each side capable of covering up to 45 meters. This makes them ideal for safeguarding hazardous areas that require enclosed regional protection, including turret punch presses, assembly stations, packaging equipment, stackers, and robot work zones.

Multi-Zone Area Protection

Operational Mechanism

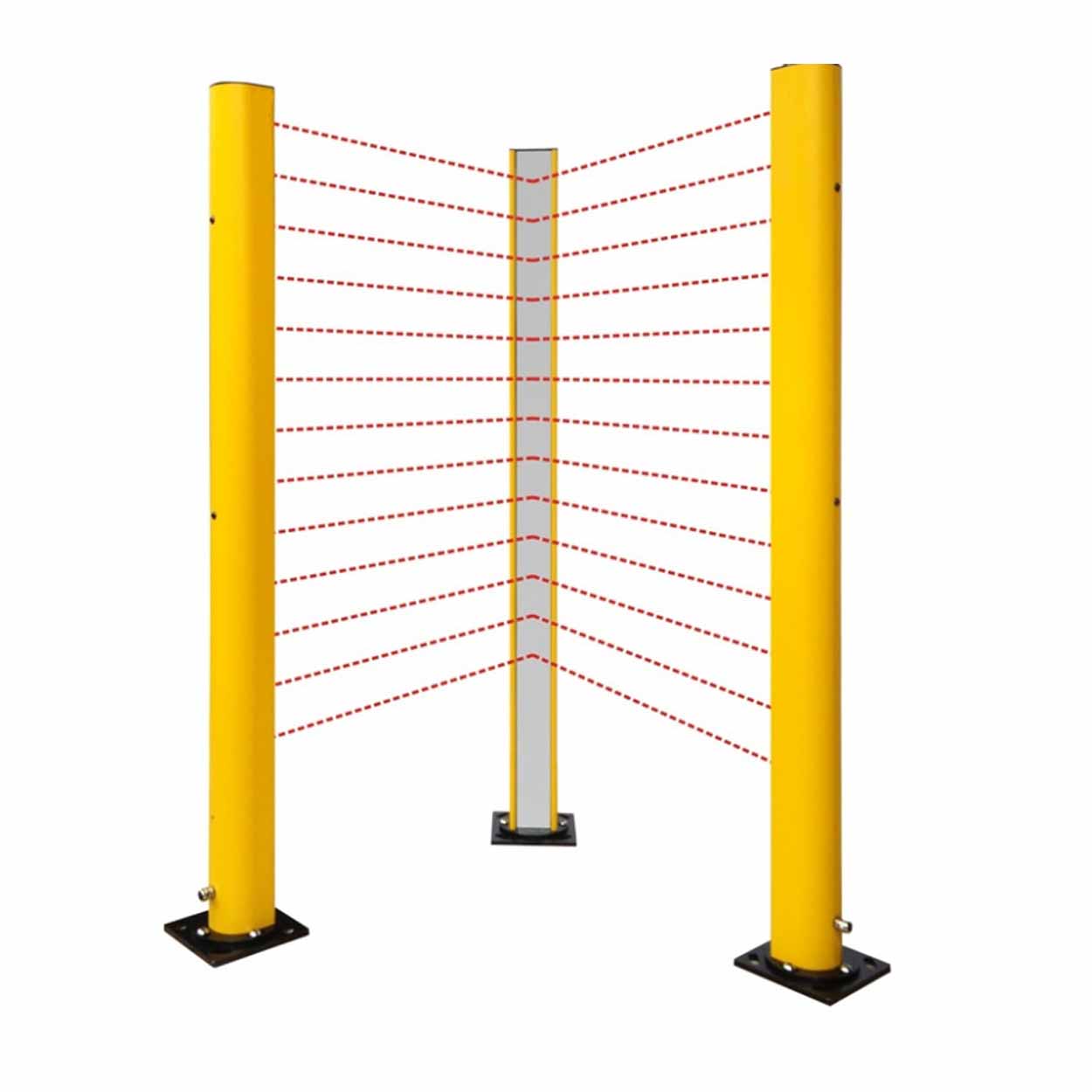

The safety light curtain operates by emitting detection beams from the transmitter. These beams are then reflected by mirrors and captured by the receiver. By manipulating the infrared light between the transmitter, reflector, and receiver, various protection configurations can be established to meet specific safety requirements.

Customizable Protection Combinations

The flexibility in configuring protection zones allows these light curtains to cater to diverse industrial setups. Whether it’s a single-zone protection or multiple overlapping zones, the system can be tailored to provide optimal safety coverage.

Wide Applicability Across Industrial Settings

Enhanced Shock Resistance

Thanks to the integration of surface-mount technology, these light curtains are exceptionally resistant to shocks. This makes them suitable for environments where machinery and equipment generate significant vibrations, ensuring reliable operation without frequent maintenance.

Durability and Customization

Robust Construction

The adoption of surface-mount technology not only enhances shock resistance but also contributes to the overall durability of the light curtains. This robust construction ensures long-term performance even in demanding industrial settings.

Adjustable Protection Areas

Users can customize the protection areas to suit their specific needs, choosing from 1-side, 2-side, 3-side, or 4-side protection. The maximum protection range for a single side extends up to 45 meters, providing ample coverage for large industrial zones..

Technical Specifications

Detailed Specifications Table

| Feature | Specification |

|---|---|

| Light Curtain Type | Opposed Beam |

| Light Axis Spacing | 20mm, 40mm, 80mm, 200mm |

| Detection Accuracy | 28mm, 48mm, 88mm, 208mm |

| Number of Beams | 6, 8, 10…72; 4, 6, 8…72; 4, 6, 8…52; 4, 6, 8…22 |

| Dimensions | 35×51×L mm (L is the length of emitter/receiver) |

| Protection Level | IP65 |

| Power Supply Voltage | DC12/24V, AC110-220V (Relay Output) |

| Current Consumption | ≤200mA |

| Output | NPN/PNP Type, input current 500mA, voltage below 1.5V, polarity, short circuit, over-cut protection |

| Output Status | ON (Receiver indicates green light) |

| Indicators | Emitter: Power indicator (red); Receiver: Output indicator light (green) – transparent (red) |

| Light Source | Modulated Infrared LED |

| Power Consumption | 15W |

| Applicable Temperature | -10°C to 50°C |

| Ambient Temperature | 20°C, RH ≤85% |

| Response Time | <15ms (including controller) |

| Insulation Resistance | >100MΩ |

| Dielectric Strength | AC150V, 60s |

| Anti-Light Interference | 10,000 Lux (incident angle ≥5°) |

| Relay Life | ≥1 million times (replaceable) |

| Protection Height | H = Light axis spacing × (Number of beams -1) |

Installation and Maintenance

Easy Integration

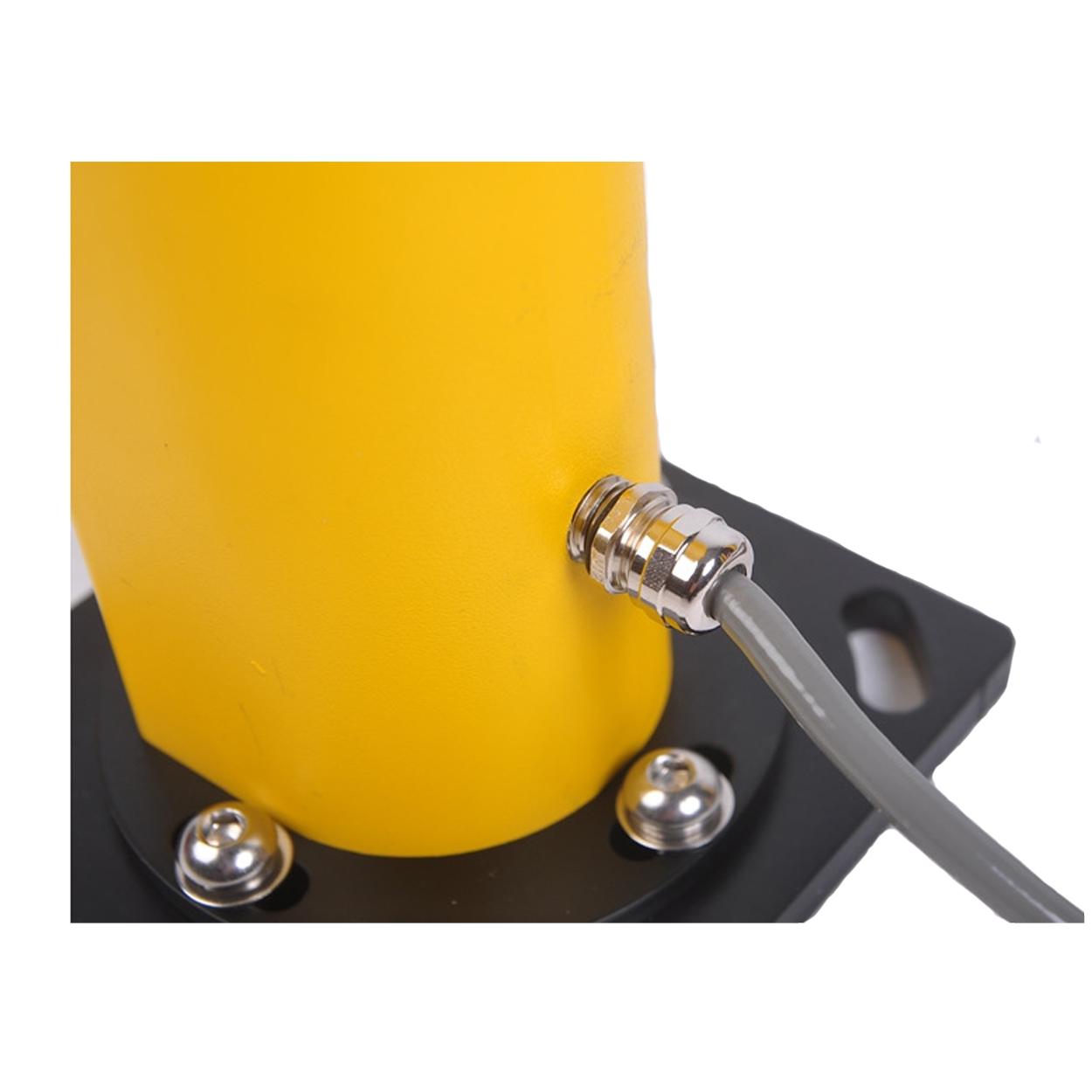

The design of these light curtains allows for straightforward installation in existing industrial setups. Their modular nature ensures that they can be seamlessly integrated with various machinery and equipment without extensive modifications.

Low Maintenance Requirements

Due to their durable construction and shock-resistant features, these safety sensors require minimal maintenance. Regular inspections are recommended to ensure optimal performance, but the robust design minimizes the need for frequent repairs or replacements.

Conclusion

Inductive industrial safety sensor machine light curtains offer a reliable and adaptable solution for ensuring workplace safety in diverse industrial environments. Their advanced technology, combined with customizable protection options and durable construction, makes them an essential component for safeguarding operators and machinery alike. By providing comprehensive protection against potential hazards, these light curtains contribute to a safer and more efficient industrial workspace.

Why Choose Us

Safe Light Guard

Our Safety Light Curtains represent a significant advancement in protective safety technology. With their robust construction, fast response times, and compliance with international safety standards, these sensors provide a critical safety function in various industrial settings. By integrating these systems, businesses can enhance operational safety and protect their most valuable assets— their people and their machinery.

Industrial Safety Upgrade

Incorporating safety light curtain sensors into industrial operations not only complies with legal safety standards but also promotes a culture of safety and responsibility. This technology is a cornerstone in modern industrial safety practices, playing a pivotal role in preventing accidents and enhancing overall workplace safety.

Frequently Asked Question

Know what you want to know about the barrier curtain sensors.

- Inductive industrial safety sensor machine light curtains are advanced safety devices that use retro-reflective mirror technology to create a network of infrared protection. They are designed to adapt to various industrial environments, offering flexible protection options from one to four sides with a maximum protection distance of up to 45 meters per side. These light curtains are ideal for safeguarding hazardous areas such as turret punch presses, assembly stations, packaging equipment, stackers, and robot work zones.

These safety light curtains are highly versatile and can be effectively applied in numerous industrial settings, including:

- Turret Punch Presses: Protecting operators from moving parts.

- Assembly Stations: Ensuring safety during assembly operations.

- Packaging Equipment: Preventing accidents in automated packaging lines.

- Palletizing Machines: Safeguarding areas where goods are stacked.

- Robot Work Zones: Providing safety around robotic arms and automated systems.

- These light curtains are designed for easy integration into existing industrial environments. Their modular construction allows for straightforward installation with minimal modifications to existing machinery and equipment. This ensures that they can be seamlessly incorporated without significant downtime or disruption to operations.

- The maximum protection range for a single side of these light curtains extends up to 45 meters. This extensive range allows for comprehensive coverage of large industrial areas, ensuring that operators and machinery are well-protected from potential hazards.

- The protection areas offered by these safety sensors are highly customizable. Users can select from 1-side, 2-side, 3-side, or 4-side protection configurations. Additionally, the protection range for a single side can extend up to 45 meters, allowing for extensive coverage tailored to the specific needs of large industrial zones.

- The multi-zone area protection operates by emitting detection beams from the transmitter. These beams are then reflected by mirrors and received by the receiver. By controlling the infrared light between the transmitter, reflector, and receiver, various protection configurations can be established. This allows for the creation of multiple protection zones tailored to specific safety requirements within an industrial setup.

- The inductive safety sensor light curtains require minimal maintenance due to their durable construction and shock-resistant features. Regular inspections are recommended to ensure optimal performance, but the robust design minimizes the need for frequent repairs or replacements. The relay components are replaceable and have a long lifespan of over one million operations.

- These light curtains are equipped with features to mitigate light interference effectively. They utilize modulated infrared LEDs and are designed to withstand up to 10,000 Lux of ambient light with an incident angle of ≥5°. This ensures that the detection beams remain reliable and accurate even in environments with high levels of ambient light, maintaining consistent protection.

Safety Curtain Sensors, Photoelectric Sensors, Proximity Sensors, Mesauring Sesnors, LED Tower Light