Low Price Laser Safety Light Barrier Curtain Manufacturers

Overview of Laser Safety Light Barrier Curtains

Definition and Functionality

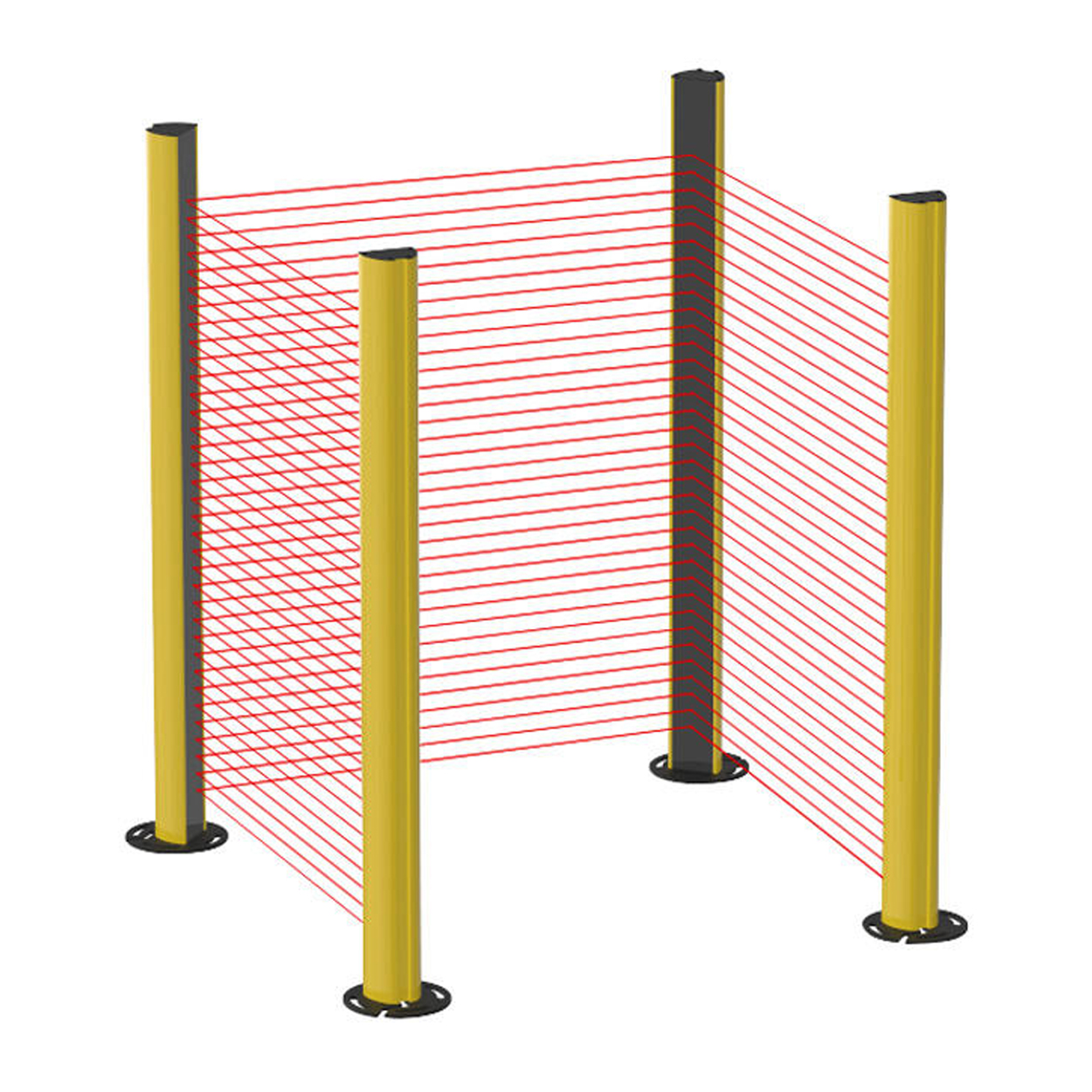

A Laser Safety Light Barrier Curtain is a sophisticated photoelectric safety device designed to create an invisible barrier using laser beams. These curtains serve as a protective measure, detecting any intrusion by objects or individuals into designated hazardous zones. Upon detection, the system promptly halts machinery operations, thereby preventing injuries and minimizing downtime.

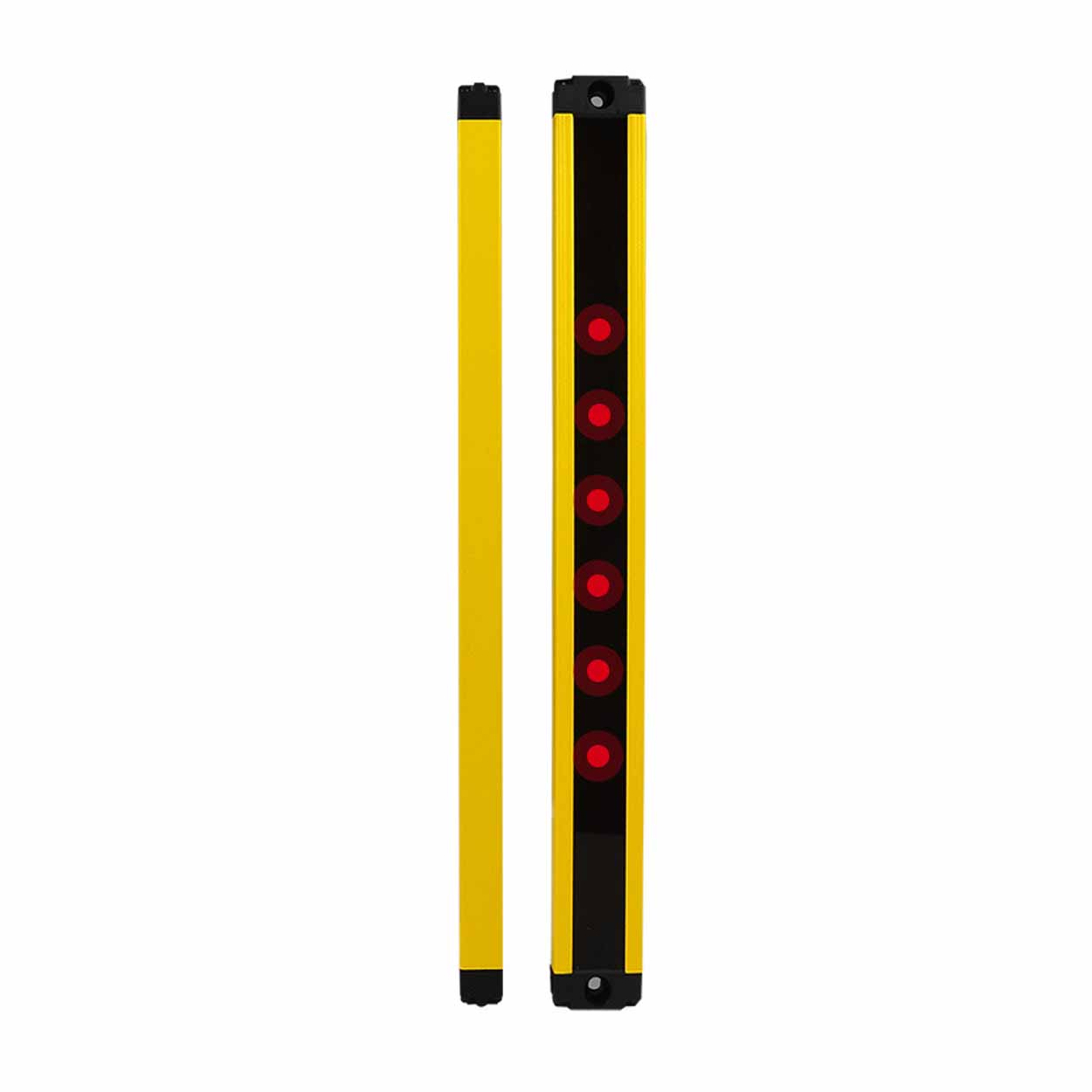

Components of a Light Curtain Sensor

The primary components of a laser safety light curtain include:

- Laser Emitters: Responsible for projecting laser beams across the protected area.

- Laser Receivers: Detect interruptions in the laser beams caused by intrusions.

- Control Unit: Processes signals from the receivers and initiates safety protocols.

- External Relay Contacts: Facilitate monitoring functions and ensure seamless integration with existing machinery.

Advantages of Laser Safety Light Barrier Curtains

Laser safety light curtains offer numerous benefits that enhance operational safety and efficiency:

- External Relay Contacts Monitoring Function: Enables real-time monitoring and quick response to safety breaches.

- Higher Detection Capability: Capable of detecting objects up to 14mm, providing robust protection for fingers and other body parts.

- Extended Detection Range: Effective over distances up to 6 meters, accommodating large workspaces.

- Infrared Light Communication and Dedicated Optical System: Ensures reliable signal transmission and minimizes false alarms.

- Overload and Short-Circuit Protection: Safeguards the system against electrical anomalies, enhancing longevity.

- Superior Damping Performance: Ideal for high-speed press operations with varying tonnages, ensuring consistent performance.

- Resistance to Light and Electromagnetic Interference: Maintains system stability in diverse environmental conditions.

Comparative Advantages of Laser Safety Light Barrier Curtains

| Feature | Description |

|---|---|

| External Relay Contacts Monitoring | Real-time monitoring and immediate safety response. |

| Detection Capability | Detects objects as small as 14mm, protecting against finger injuries. |

| Detection Range | Operates effectively up to 6 meters, suitable for expansive areas. |

| Infrared Communication | Utilizes infrared light for reliable and precise signal transmission. |

| Overload & Short-Circuit Protection | Protects against electrical faults, ensuring system durability. |

| Damping Performance | Excellent performance in high-speed, high-tonnage press environments. |

| Interference Resistance | Strong resistance to light and electromagnetic disturbances. |

Technical Specifications

Detection Capability

Laser safety light curtains are engineered to detect objects with high precision. Their capability to identify obstructions as small as 14mm ensures comprehensive protection for operators’ fingers and other vulnerable body parts during machine operation.

Detection Range

With an impressive detection range of up to 6 meters, these light curtains are suitable for large-scale industrial settings. This extensive range allows for effective coverage of expansive work areas, enhancing overall safety without compromising operational efficiency.

Working Principle

Infrared Transmitting and Receiving Tubes

A laser safety light curtain comprises multiple infrared transmitting and receiving tubes arranged in a straight line. The transmitters project laser beams towards the receivers, creating an invisible grid of protection across the designated area.

Infrared Transmitting and Receiving Tubes

A laser safety light curtain comprises multiple infrared transmitting and receiving tubes arranged in a straight line. The transmitters project laser beams towards the receivers, creating an invisible grid of protection across the designated area.

Signal Processing and Safety Response

When an object breaches the laser grid by interrupting one or more beams, the receivers detect the change and send signals to the control unit. The control unit then activates safety protocols, such as stopping machinery operations, to prevent accidents and injuries.

Applications of Laser Safety Light Barrier Curtains

Industrial Machinery Protection

Safety Light Barrier Curtains in manufacturing environments, laser safety light curtains are indispensable for safeguarding operators from moving machinery parts. They are commonly integrated into stamping equipment, presses, and automated assembly lines to ensure continuous protection.

High-Speed Press Equipment

Laser light curtains excel in high-speed press operations where rapid movements pose significant safety risks. Their superior damping performance and quick response times make them ideal for environments with varying tonnages and high operational speeds.

Robotics and Automation

As industries increasingly adopt robotics and automation, the need for reliable safety measures grows. Laser safety light curtains provide an effective barrier, ensuring that human operators and robotic systems can coexist safely within shared workspaces.

Case Studies: Successful Implementations

Automotive Manufacturing

In an automotive manufacturing plant, the integration of laser safety light curtains significantly reduced workplace accidents. By installing these light curtains around robotic welding stations, the plant ensured that any unintended intrusion by operators led to an immediate halt in operations, thereby preventing injuries and enhancing overall safety.

Food Processing Industry

A food processing facility implemented laser safety light curtains to protect workers from automated slicing machines. The system’s high detection range and reliability ensured that any obstruction by hands or other body parts triggered a swift response, maintaining a safe and efficient production environment.

Robotics and Automation

Why Choose Us

Safe Light Guard

Our Safety Light Curtains represent a significant advancement in protective safety technology. With their robust construction, fast response times, and compliance with international safety standards, these sensors provide a critical safety function in various industrial settings. By integrating these systems, businesses can enhance operational safety and protect their most valuable assets— their people and their machinery.

Industrial Safety Upgrade

Incorporating safety light curtain sensors into industrial operations not only complies with legal safety standards but also promotes a culture of safety and responsibility. This technology is a cornerstone in modern industrial safety practices, playing a pivotal role in preventing accidents and enhancing overall workplace safety.

Frequently Asked Question

Know what you want to know about the barrier curtain sensors.

- While laser safety light curtains are designed for durability and reliability, regular maintenance is recommended to ensure optimal performance. This includes cleaning the components, inspecting for wear and tear, and conducting system tests to verify functionality.

With proper maintenance and usage, laser safety light curtains can have a long service life. Many manufacturers provide warranties of up to one year, with the potential for extended longevity based on the quality of components and maintenance practices.

- Our light curtains can detect objects as small as 14mm, providing exceptional fine-level protection that is particularly effective in safeguarding operators’ fingers during intricate handling or assembly processes.

- The interruption of the infrared beam instantly triggers a signal within the light curtain’s control circuit. This signal is then sent to the connected machinery, prompting immediate safety actions—such as emergency braking—to prevent injury or damage.

- Yes, manufacturers offer customization options to tailor laser safety light curtains to meet the unique requirements of various industrial applications. This includes customizing the wiring boards of photoelectric sensors and adjusting detection ranges.

- Laser safety light curtains offer greater flexibility, ease of integration, and precise detection capabilities compared to traditional safety barriers. They do not impede movement and can be easily adjusted to accommodate changing operational needs.

- Yes. They feature strong resistance to both light interference and electromagnetic interference, ensuring stable and reliable operation even in harsh industrial environments where external signals could otherwise cause malfunctions.

- es. We provide customized solutions to meet unique requirements regarding the photoelectric sensor’s wiring board, ensuring seamless integration into your existing systems and adherence to specialized operational demands.

Safety Curtain Sensors, Photoelectric Sensors, Proximity Sensors, Mesauring Sesnors, LED Tower Light