Automobile Induction Area Safety Light Curtains for Machine

Advanced Safety Light Curtain Technologies: Enhancing Workplace Safety

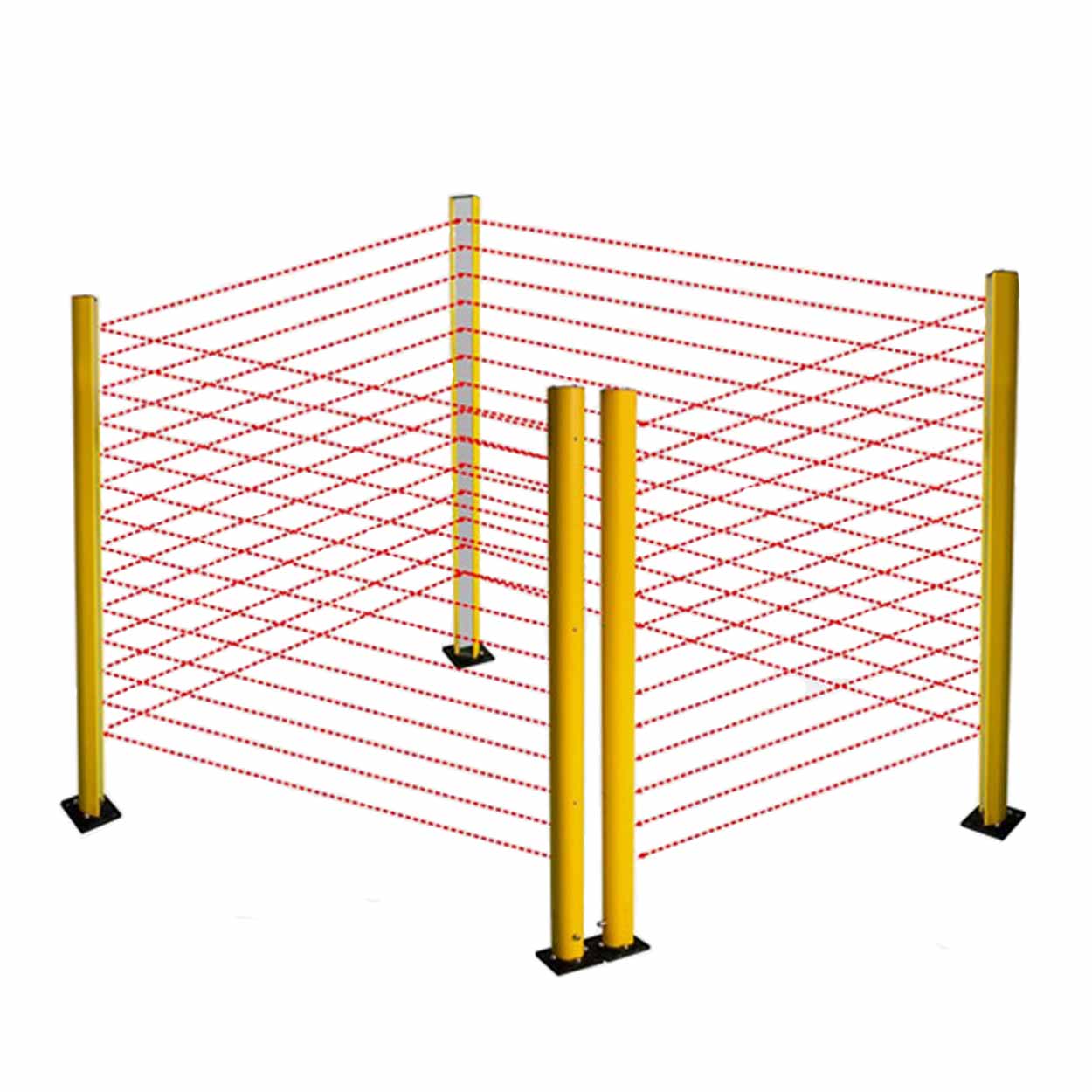

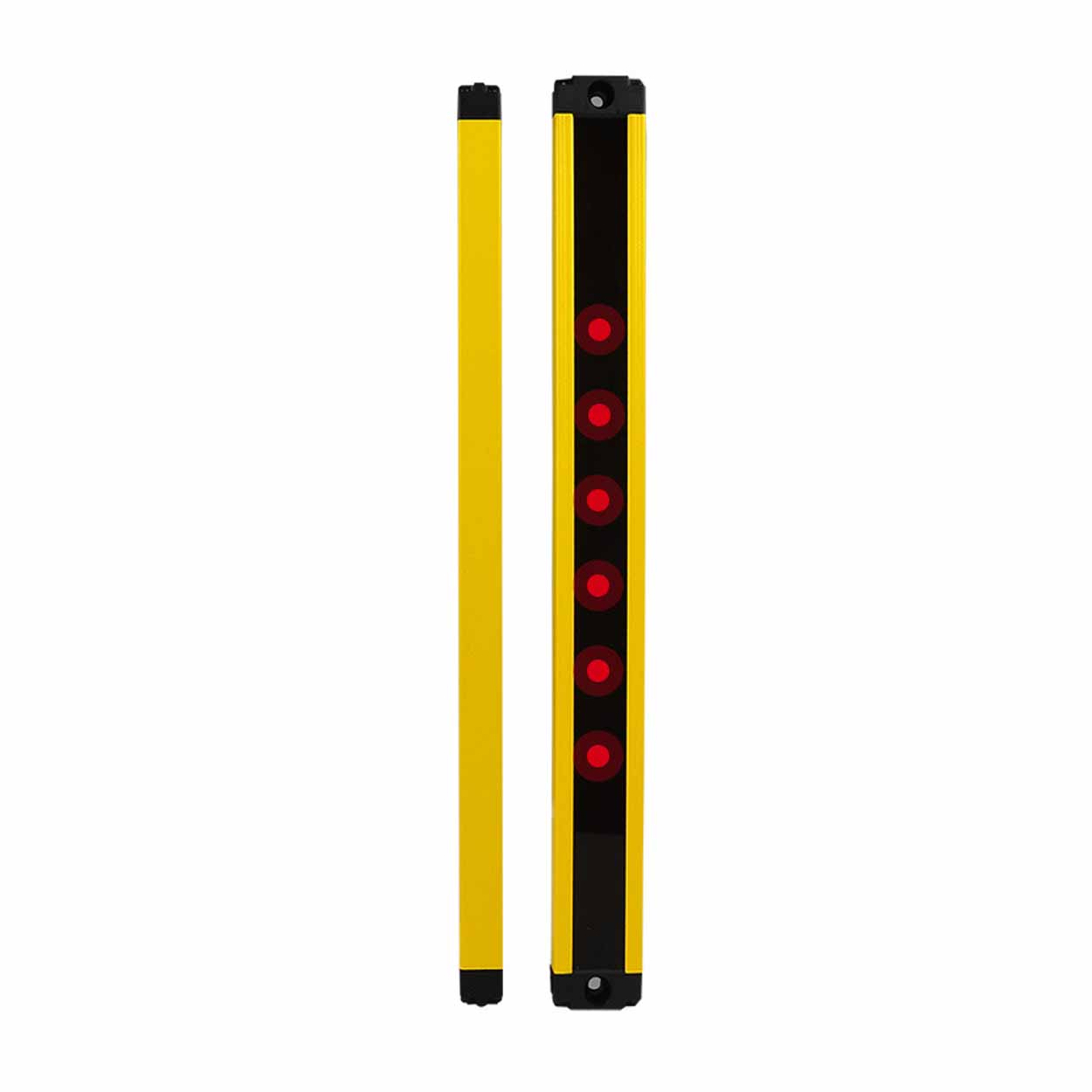

Safety light curtains are a critical component in modern industrial safety, providing an invisible barrier designed to protect workers from hazardous machinery. These systems, consisting of a light emitter and receiver, are engineered to detect any opaque objects that interrupt the light beams within the curtain, triggering machinery to halt operations immediately. This innovative technology offers a rapid response time of less than 1ms and operates effectively across a wide voltage range (DC10~30V). Featuring line synchronization technology and robust anti-electromagnetic and anti-light interference capabilities, safety light curtains ensure reliable and stable performance in diverse industrial environments.

Key Features and Benefits

- Rapid Response Time: At less than 1ms, the system reacts instantaneously to potential hazards.

- Voltage Flexibility: Operates on a low, wide voltage range from DC10 to 30V, accommodating various industrial settings.

- Advanced Synchronization: Utilizes line synchronization technology to enhance performance under various light conditions.

- Electromagnetic Compatibility: Designed to resist electromagnetic disturbances from other industrial equipment.

- Durable Materials: Constructed from tough, stable materials for long-lasting use.

- Ease of Installation: The system is designed for straightforward installation and removal.

Safety light curtains are especially suited for use with paper machinery, leather and woodworking machinery, injection molding machines, and other heavy industrial equipment where precision and safety are paramount.

Technical Specifications

| Feature | Specification |

|---|---|

| Response Time | <1ms |

| Operating Voltage | DC10~24V |

| Interference Resistance | High anti-electromagnetic and anti-light interference |

| Material Durability | Designed for long-term use |

| Installation | Easy to install and remove |

| Applications | Paper machinery, woodworking, leather processing, etc. |

Applications in Industry

Safety light curtains are vital in various manufacturing and processing industries. They are commonly installed around equipment such as paper cutters, conveyors, assembly lines, and more, to prevent accidents and enhance the safety of the working environment.

Enhanced Safety Protocols

The integration of safety light curtains with machine control systems, such as PLCs and safety relays, allows for sophisticated safety protocols. In the event of a detection, these curtains can trigger an automatic shutdown of machinery, preventing potential injuries and enhancing overall workplace safety.

Compliance and Standards

The technology behind safety light curtains adheres to rigorous international safety standards, including NR12 and the RoHS European directive. These standards ensure that the devices are not only effective but also safe for use in various industrial applications.

Conclusion

The implementation of safety light curtains across industries marks a significant advancement in occupational safety. These systems not only provide an effective means of protecting workers but also integrate seamlessly with existing machinery and control systems, making them an indispensable part of modern industrial operations. As technology progresses, the capabilities of these safety devices will continue to evolve, further enhancing their effectiveness in protecting human lives.

Why Choose Us

Safe Light Guard

Our Safety Light Curtains represent a significant advancement in protective safety technology. With their robust construction, fast response times, and compliance with international safety standards, these sensors provide a critical safety function in various industrial settings. By integrating these systems, businesses can enhance operational safety and protect their most valuable assets— their people and their machinery.

Industrial Safety Upgrade

Incorporating safety light curtain sensors into industrial operations not only complies with legal safety standards but also promotes a culture of safety and responsibility. This technology is a cornerstone in modern industrial safety practices, playing a pivotal role in preventing accidents and enhancing overall workplace safety.

Frequently Asked Question

Know More About the Safety Light Curtains

- Safety light curtains offer a rapid response time of less than 1 millisecond, ensuring quick reaction to potential hazards.

- Yes, safety light curtains comply with international safety standards, including NR12 and the RoHS European directive, ensuring safe operation.

- They are commonly used with paper machinery, leather machinery, woodworking machinery, injection molding machines, and other heavy industrial equipment.

- They are equipped with line synchronization technology and have strong anti-light and anti-electromagnetic interference capabilities, ensuring stable operation even in challenging environments.

- By detecting any opaque objects that interrupt the light beams, these curtains trigger an automatic shutdown of machinery, preventing accidents and injuries.

- Safety light curtains feature programmable functions such as floating and fixed blanking, allowing for customized setup based on specific safety requirements.