Automatic Secure Non Contact Safety Detection Area Sensors

Advanced Detection Area Sensors: Enhancing Precision and Safety in Modern Applications

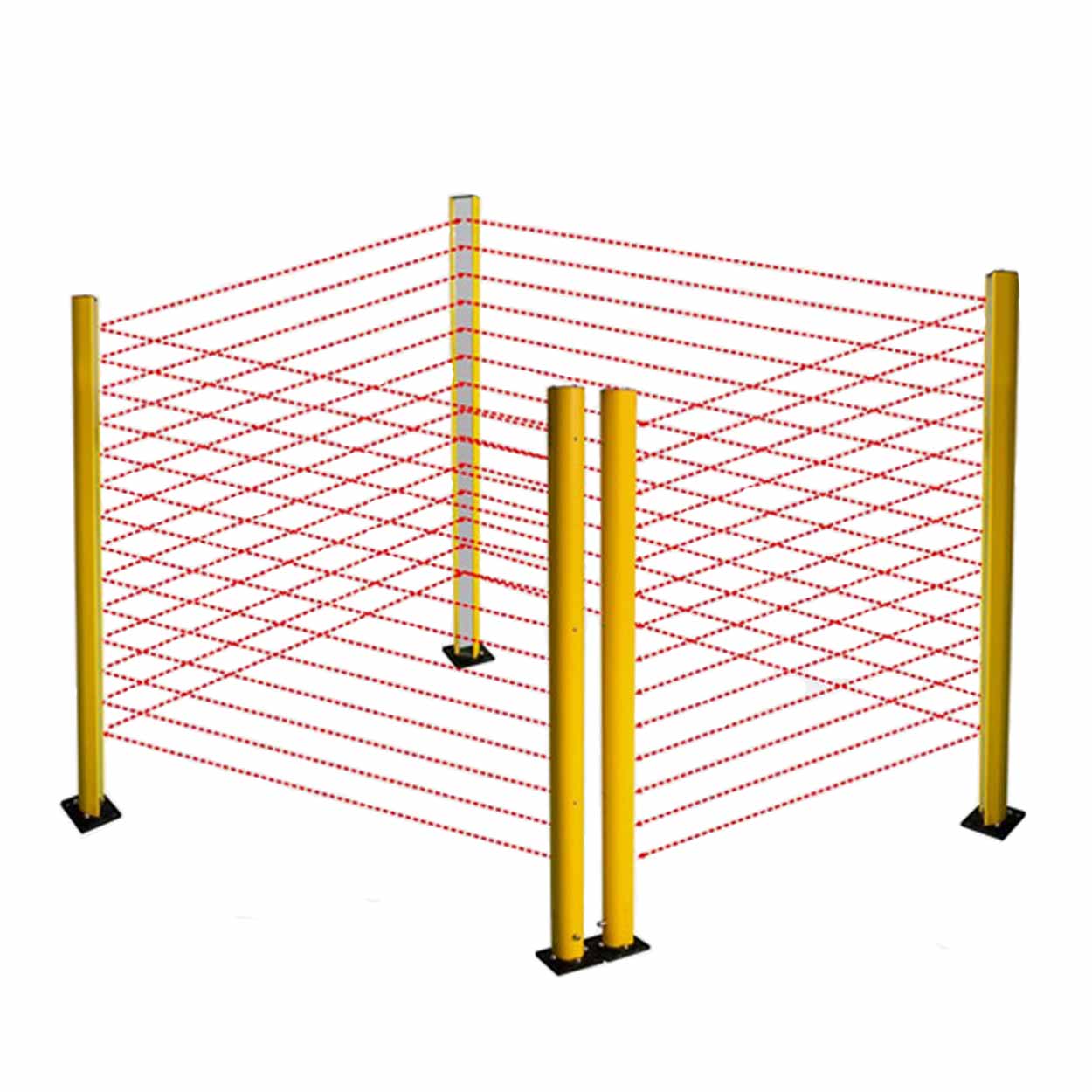

Detection area sensors are sophisticated multi-beam arrays of photoeyes designed to monitor presence within the controlled height of the sensor array. These sensors excel in identifying objects of varying sizes and shapes at random positions as they traverse the two-dimensional target area. Recently, the scope of detection area sensors has broadened to include wide area sensors tailored for comprehensive object detection. These enhanced sensors utilize multi-beam, through-beam configurations with dedicated emitter and receiver elements to detect objects by assessing the light beam intensity received. Furthermore, these area sensors boast an IEC IP67 ingress protection rating, ensuring robust performance in diverse environmental conditions.

Introduction to Detection Area Sensors

Detection area sensors play a pivotal role in modern automation and safety systems by providing reliable object detection within specified areas. These sensors utilize an array of photoeyes arranged in a multi-beam configuration to monitor and detect the presence of objects passing through the defined target area. The ability to detect objects of varying sizes and shapes at random positions makes these sensors indispensable in applications ranging from industrial automation to security systems.

Expanded Sensor Offerings

Wide Area Sensors

The evolution of detection area sensors has led to the introduction of wide area sensors, which extend the coverage area for more comprehensive object detection. These sensors are designed to monitor larger spaces, ensuring that no object goes undetected within the expanded range. The integration of wide area sensors enhances the overall monitoring capabilities, making them suitable for expansive industrial settings and large-scale security installations.

Multi-Beam Through-Beam Configuration

Modern detection area sensors employ a multi-beam, through-beam configuration, which consists of separate emitter and receiver elements positioned opposite each other. This setup allows for precise detection by measuring the intensity of the light beam that returns to the receiver. Any interruption or alteration in the beam intensity indicates the presence of an object, enabling accurate and reliable detection across the entire monitored area.

Teach-In Functions

Fine Teach

Fine Teach is a feature that allows the sensor to detect the smallest objects with high precision. This function is crucial in applications where detecting minute objects is essential, such as in quality control processes or intricate assembly lines. By adjusting the sensitivity, Fine Teach ensures that even the tiniest obstructions are promptly identified, enhancing the sensor’s overall effectiveness.

Gross Teach

On the other hand, Gross Teach is designed to mitigate potential stability and repeatability issues by reducing sensitivity to environmental fluctuations. This function is particularly beneficial in environments with variable lighting conditions or where minor obstructions might otherwise trigger false detections. Gross Teach ensures that the sensor maintains consistent performance by focusing on significant interruptions rather than minor variances.

Emitter Technology

The Emitter in detection area sensors plays a critical role by emitting near-infrared light at non-dangerous levels. This technology ensures safe operation while providing the necessary illumination for accurate detection. The use of near-infrared light allows the sensor to function effectively in various lighting conditions without posing any risk to personnel or the environment.

Key Features and Benefits

Fast Reaction Time

Detection area sensors are engineered for fast reaction times, with some models responding as quickly as 0.01 seconds. This rapid response capability ensures that objects are detected almost instantaneously as they pass through the target area. The detection distance between the transmitter and receiver can extend up to 5 meters, providing ample coverage for large spaces. Notably, the beam pitch of all types of safety light curtains is 40mm, making them ideal for detecting wrist or body movements accurately.

Security Enhancements

These sensors significantly contribute to personal safety and workplace security by preventing unauthorized access and reducing the risk of work-related injuries. Research indicates that 90% of work-related injuries stem from inadequate safety measures. By deploying heavy duty drawer slides and robust detection systems, safety grating effectively safeguards personnel, ensuring a secure working environment.

Stable Output

One of the standout features of these area sensors is their stable output. They do not require a synchronization line as the power supply can be provided separately. This design choice allows the sensors to resist electromagnetic interference, ensuring reliable performance even in electrically noisy environments. The stable output guarantees consistent detection accuracy, which is vital for critical applications.

Stable Output

One of the standout features of these area sensors is their stable output. They do not require a synchronization line as the power supply can be provided separately. This design choice allows the sensors to resist electromagnetic interference, ensuring reliable performance even in electrically noisy environments. The stable output guarantees consistent detection accuracy, which is vital for critical applications.

Wide Application Range

Detection area sensors boast a broad range of applications, making them versatile tools in various industries. They are suitable for machine tool operation areas, production lines, automatic welding lines, cutting and pressing equipment, and more. Additionally, with a high protection grade of IP65, these sensors are well-suited for diverse working environments, including those exposed to dust and water.

Superior Quality

- The safety light curtains incorporated into these detection area sensors feature high-brightness indicator lights, making their operational status easily identifiable. The surfaces are treated with high-quality baking varnish, rendering them waterproof, oil-proof, and well-sealed. This high standard of quality ensures that the sensors remain functional and reliable under demanding conditions, providing long-term value and performance.

Technical Specifications

| Feature | Specification |

|---|---|

| Ingress Protection | IEC IP67 |

| Reaction Time | 0.01 seconds |

| Detection Distance | Up to 5 meters |

| Beam Pitch | 40mm |

| Surface Material | Prefabricated rubber, Polyurethane |

| Emitter Type | Near-infrared light |

| Certification | CE |

| Teach-In Levels | Fine Teach, Gross Teach |

| Load Capacity | Varies (up to 500 lbs) |

| Operating Environment | Industrial, Commercial, Residential |

| Power Supply | Separate, no synchronization line needed |

| Indicators | LEDs for status, alignment, faults |

| Material Technologies | EPDM, Vulcanized Rubber |

Applications in Various Industries

Industrial Manufacturing

- In industrial manufacturing, detection area sensors are integral to automating processes and ensuring safety. They are deployed in assembly lines, machinery operation areas, and storage systems to monitor the movement and presence of objects, preventing accidents and optimizing workflow efficiency. The robust construction and high load capacity of these sensors make them ideal for the harsh conditions typical of industrial environments.

Automotive Sector

- The automotive sector leverages detection area sensors in various applications, including assembly lines, quality control stations, and automated equipment. These sensors ensure precise alignment and movement of automotive components, enhancing production accuracy and reducing the likelihood of defects. Their ability to detect both large and small objects quickly supports the high-speed demands of automotive manufacturing.

Warehouse Management

- In warehouse management, detection area sensors streamline operations by monitoring inventory movement and ensuring the safe operation of storage systems. They are used in conveyor systems, automated retrieval systems, and safety barriers to manage the flow of goods efficiently. The fast reaction time and reliable performance of these sensors help maintain smooth and safe warehouse operations.

Installation and Maintenance

Installation Guidelines

Proper installation of detection area sensors is crucial to their performance and longevity. Here are some guidelines to ensure a successful setup:

- Site Assessment: Evaluate the installation area to determine the optimal placement of emitters and receivers, ensuring comprehensive coverage of the target area.

- Mounting: Securely mount the emitter and receiver elements, maintaining the specified beam pitch of 40mm. Ensure that the components are aligned correctly to prevent misdetections.

- Power Supply: Provide a separate power supply to avoid interference from other electrical systems. Ensure that the power connections are stable and protected against environmental factors.

- Calibration: Utilize the teach-in functions to calibrate the sensor’s sensitivity levels. Fine Teach for small object detection and Gross Teach for enhanced stability and reduced sensitivity to environmental changes.

Maintenance Best Practices

Maintaining detection area sensors involves regular inspections and cleaning to ensure optimal functionality:

- Regular Cleaning: Keep the sensor lenses and surfaces free from dust, dirt, and obstructions to maintain accurate detection.

- Routine Inspections: Periodically check the alignment and condition of the emitter and receiver elements. Look for signs of wear, corrosion, or damage.

- Lubrication: Apply appropriate lubricants to moving parts, if applicable, to reduce friction and prevent wear.

- Firmware Updates: If the sensors are equipped with firmware, ensure they are updated regularly to benefit from performance improvements and bug fixes.

Future Trends in Detection Area Sensors

The field of detection area sensors is continually evolving, driven by advancements in technology and the growing demand for more sophisticated safety and automation solutions. Future trends include:

- Integration with IoT: Enhanced connectivity allows sensors to communicate with other devices and systems, enabling smarter and more responsive automation.

- AI and Machine Learning: Incorporating AI algorithms to improve object recognition accuracy and predictive maintenance capabilities.

- Miniaturization: Developing smaller, more compact sensors without compromising on performance, suitable for space-constrained applications.

- Energy Efficiency: Designing sensors that consume less power while maintaining high detection accuracy and speed.

- Enhanced Durability: Using advanced materials and coatings to further improve resistance to harsh environmental conditions and extend sensor lifespan.

Conclusion

- Detection area sensors have become indispensable in ensuring safety and efficiency across various industries. Their ability to accurately detect objects of different sizes and shapes within a defined area, combined with features like fast reaction times, robust materials, and versatile mounting options, make them ideal for a wide range of applications. By understanding the different types, functionalities, and benefits of these sensors, organizations can make informed decisions to enhance their operational safety and efficiency.

Why Choose Us

Safe Light Guard

Our Safety Light Curtains represent a significant advancement in protective safety technology. With their robust construction, fast response times, and compliance with international safety standards, these sensors provide a critical safety function in various industrial settings. By integrating these systems, businesses can enhance operational safety and protect their most valuable assets— their people and their machinery.

Industrial Safety Upgrade

Incorporating safety light curtain sensors into industrial operations not only complies with legal safety standards but also promotes a culture of safety and responsibility. This technology is a cornerstone in modern industrial safety practices, playing a pivotal role in preventing accidents and enhancing overall workplace safety.

Frequently Asked Question

Know what you want to know about the detection area sensor.

- Detection area sensors are multi-beam arrays of photoeyes designed to monitor and detect the presence of objects within a defined two-dimensional target area. They operate by emitting light beams from emitter elements and receiving the reflected or interrupted beams with receiver elements. Any change in the light beam intensity indicates the presence of an object, allowing for precise detection and monitoring.

Teach-in functions allow users to calibrate the sensor’s sensitivity levels based on specific application needs. Fine Teach enables the detection of smaller objects by adjusting the sensor to recognize minimal interruptions, enhancing precision. Gross Teach reduces the sensor’s sensitivity to minor environmental changes, improving stability and preventing false detections in fluctuating conditions.

To ensure optimal performance, detection area sensors require regular maintenance, including:

- Cleaning: Keeping the sensor lenses and surfaces free from dust and debris.

- Inspection: Regularly checking for signs of wear, corrosion, or damage.

- Lubrication: Applying appropriate lubricants to moving parts to reduce friction.

- Calibration: Periodically recalibrating the sensor settings to maintain accuracy.

- Firmware Updates: Updating the sensor’s firmware, if applicable, to incorporate performance enhancements and security updates.

- Ball bearing mechanisms facilitate smooth and silent drawer movements by reducing friction between the sliding components. This enhances the overall reliability and longevity of the drawer slides, ensuring consistent performance even under heavy loads and frequent use.

- The IEC IP67 ingress protection rating signifies that the detection area sensors are completely dust-tight and can withstand temporary immersion in water up to 1 meter for 30 minutes. This rating ensures that the sensors perform reliably in harsh environmental conditions, making them suitable for both indoor and outdoor applications where exposure to dust and moisture is a concern.

- Yes, detection area sensors can be customized to meet the specific requirements of different applications. Customizations may include adjusting load capacities, modifying extension types (full or partial), selecting appropriate materials for different environments, and integrating additional features like soft close mechanisms or advanced LED indicators.

- Absolutely. Detection area sensors are highly versatile and can be tailored for both residential and industrial applications. In residential settings, they enhance home automation and security systems, while in industrial environments, they provide robust object detection for safety and operational efficiency.

- These light curtains are equipped with features to mitigate light interference effectively. They utilize modulated infrared LEDs and are designed to withstand up to 10,000 Lux of ambient light with an incident angle of ≥5°. This ensures that the detection beams remain reliable and accurate even in environments with high levels of ambient light, maintaining consistent protection.

Safety Curtain Sensors, Photoelectric Sensors, Proximity Sensors, Mesauring Sesnors, LED Tower Light