Body Protect Infrared Light Curtain Smart Safety Door Sensor

Comprehensive Overview of Micoguard Light Curtain

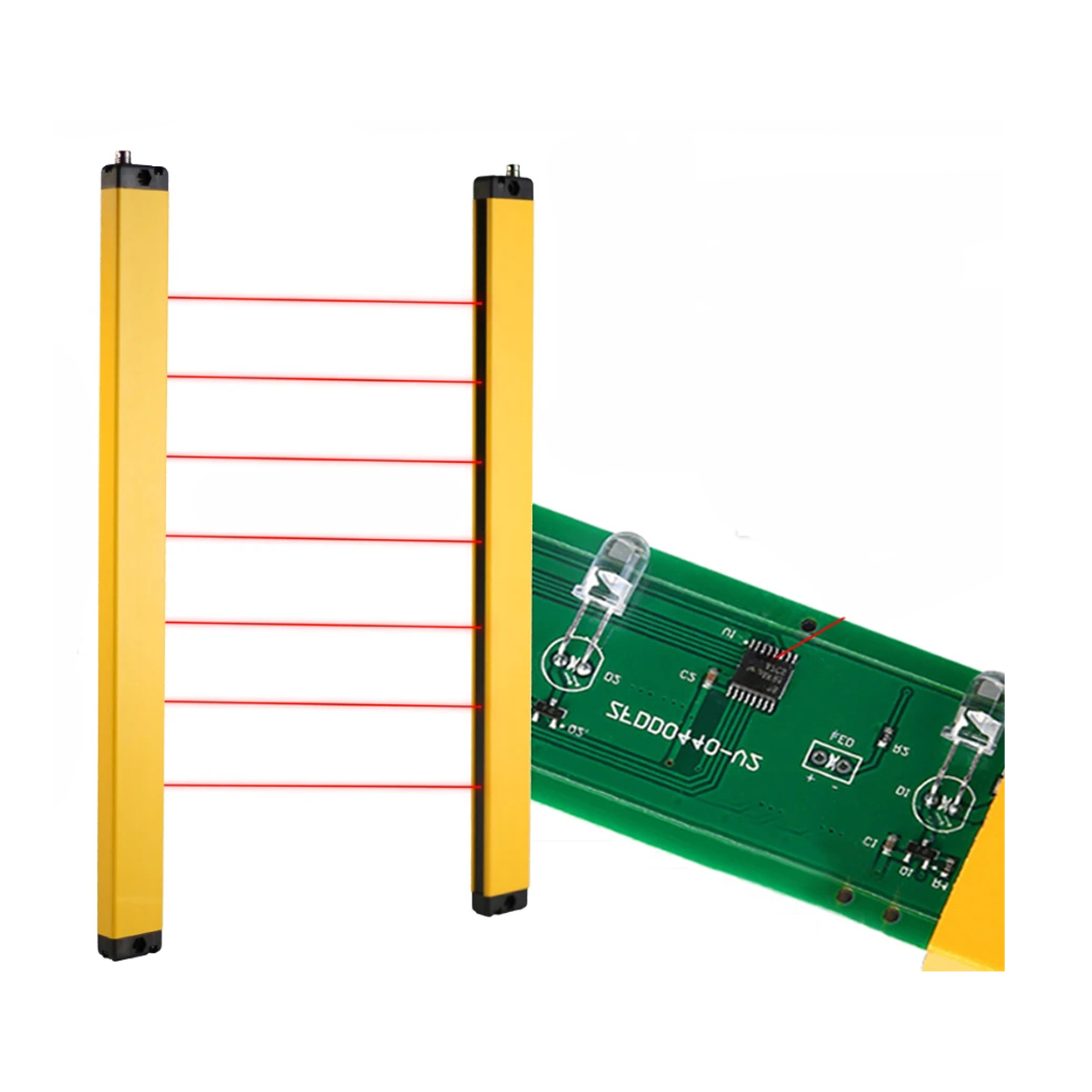

Design and Construction

The Micoguard Light Curtain Safety Distance Laser Barrier Sensor is engineered for robust protection, featuring a substantial protection height of 200mm. Constructed with a thickness of 2.0mm and housed in high-quality aluminum, the sensor is designed to endure collisions and provide reliable protection. The sturdy aluminum casing also ensures secure transportation and longevity of the device.

Functional Capabilities

Equipped with a self-diagnostic function, the Micoguard sensor can detect and report any operational errors. These error codes are communicated to the PLC or other monitoring systems, facilitating prompt corrective actions. The sensor’s laser-printed specifications and reputable branding guarantee durability and consistent performance over time.

High-Speed Response and Detection Capabilities

| Feature | Specification |

|---|

| Protection Height | 200mm |

| Housing Material | High-quality Aluminum (2.0mm thickness) |

| Beam Distance Options | 10mm, 20mm, 40mm |

| Number of Optical Axes | 4 to 500 points |

| Detection Distance | Up to 5 meters |

| Response Time | 0.01 seconds |

| Protection Grade | IP65 |

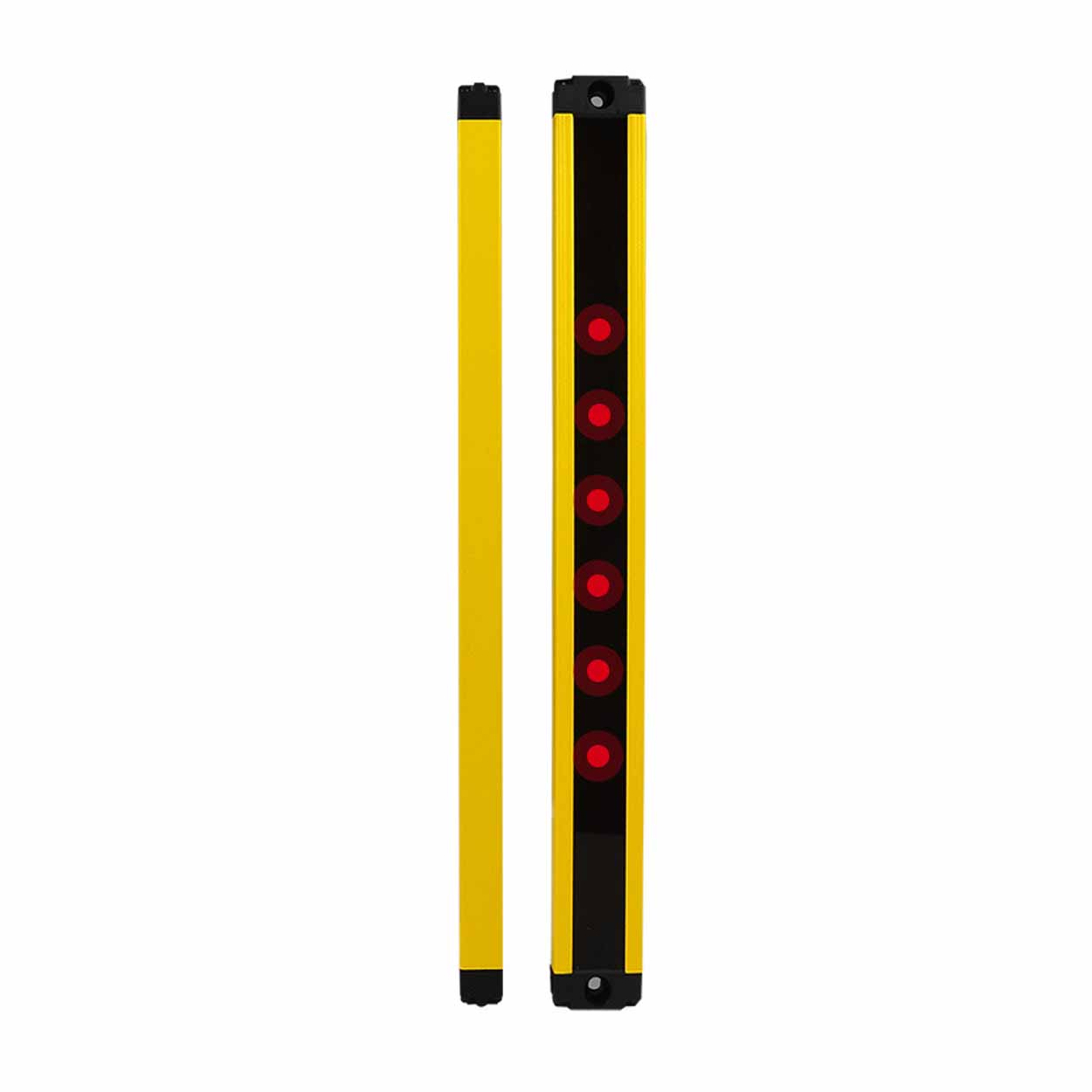

| Indicator Light | High-brightness LED |

| Surface Treatment | Waterproof, oil-proof, and sealed with baking varnish |

Application and Benefits

Industrial Safety Enhancement

The Micoguard Light Curtain is extensively utilized to ensure the safety of operators and prevent accidents during the operation of heavy and hazardous machinery. By defining a secure perimeter around dangerous equipment, the sensor minimizes the risk of accidental intrusions that could lead to work-related injuries.

Self-Diagnostic and Monitoring

The integrated self-diagnostic feature allows for real-time monitoring of the sensor’s functionality. In the event of an error, the system promptly notifies the central control unit, enabling swift maintenance and reducing downtime. This proactive approach enhances overall workplace safety and operational efficiency.

Selection Guidelines for Optimal Safety

Choosing the Appropriate Optical Axis Spacing

Selecting the correct optical axis spacing is crucial for effective protection:

- 10mm Spacing: Ideal for finger protection or safeguarding small objects.

- 20mm Spacing: Suitable for palm protection or larger objects exceeding 20mm.

- 40mm Spacing: Primarily used for arm protection or objects larger than 40mm.

Determining the Number of Optical Axes

The number of optical axes, or light beams, required depends on the height of the emitter and receiver. This can range from 4 to 500 points, ensuring comprehensive coverage and reliable detection within the protected area.

Setting the Interception Distance

The interception distance, also known as the protective length, defines the maximum distance at which the receiver can effectively capture signals from the emitter. Proper configuration of this distance is essential for maintaining the sensor’s accuracy and responsiveness.

Performance and Reliability

Rapid Response Time

With a lightning-fast response time of 0.01 seconds, the Micoguard Light Curtain ensures immediate detection of any intrusions. The extensive detection range of up to 5 meters between the transmitter and receiver allows for comprehensive monitoring of large industrial spaces.

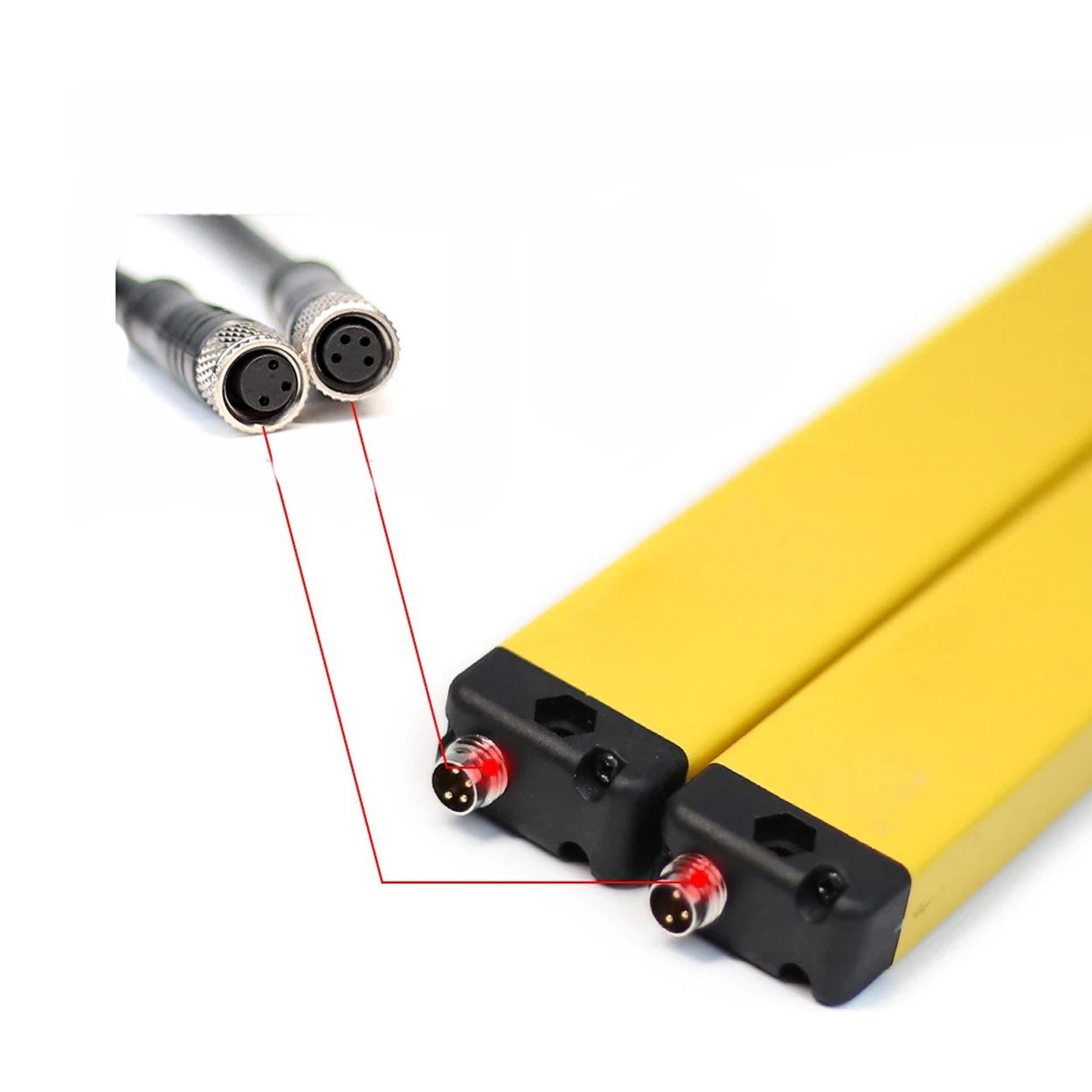

Stable and Interference-Resistant Output

The sensor operates independently of synchronization lines by utilizing a separate power supply. This design makes it highly resistant to electromagnetic interference, ensuring a stable and reliable output even in electrically noisy environments.

Quality and Durability

The Micoguard Light Curtain boasts a high-brightness indicator light, facilitating easy identification of its operational status. The surface treatment with high-quality baking varnish renders the sensor waterproof, oil-proof, and well-sealed, making it suitable for various demanding working environments.

Wide Range of Applications

This versatile safety light curtain is applicable in numerous industrial settings, including:

- Machine tool operation areas

- Production lines

- Automatic welding lines

- Automated equipment

- Cutting and pressing machinery

Its high protection grade (IP65) ensures optimal performance across different environments, enhancing workplace safety and operational continuity.

Conclusion

The Micoguard Light Curtain Safety Distance Laser Barrier Sensor stands out as a reliable and efficient solution for industrial safety. Its robust design, advanced self-diagnostic capabilities, and versatile application range make it an indispensable tool for protecting workers and ensuring the safe operation of machinery. By adhering to precise selection guidelines and leveraging its superior performance features, industries can significantly reduce work-related injuries and maintain a secure working environment.

Why Choose Us

Safe Light Guard

Our Safety Light Curtains represent a significant advancement in protective safety technology. With their robust construction, fast response times, and compliance with international safety standards, these sensors provide a critical safety function in various industrial settings. By integrating these systems, businesses can enhance operational safety and protect their most valuable assets— their people and their machinery.

Industrial Safety Upgrade

Incorporating safety light curtain sensors into industrial operations not only complies with legal safety standards but also promotes a culture of safety and responsibility. This technology is a cornerstone in modern industrial safety practices, playing a pivotal role in preventing accidents and enhancing overall workplace safety.

Frequently Asked Question

Know what you want to know about the barrier curtain sensors.

- These sensors are engineered for high-speed detection, responding to interruptions in as little as 0.01 seconds to ensure immediate protective measures.

Yes. With a rugged IP65 enclosure rating and high-quality surface treatments, the sensors resist dust, water, and oil, ensuring reliable operation in demanding environments..

- No. The sensors utilize optical synchronization technology (in integrated models), eliminating the need for hard-wired synchronization lines. This reduces installation complexity and maintenance requirements.

- Yes. The machine test signal function allows you to perform regular diagnostics on the safety system without disrupting normal operations, ensuring continuous safety compliance.

- The sensors can detect objects up to 5 meters away, offering adequate coverage and advanced warning in a variety of industrial setups.

- Absolutely. The sensors offer external device monitoring, allowing seamless integration with other safety components to form a comprehensive protective network.

- Beam coding minimizes false alarms by uniquely identifying and authenticating the signal beams. This ensures that the sensor only responds to genuine interruptions, improving overall detection accuracy.

- They are highly versatile and can be applied across diverse applications, including machine tool operations, production lines, automatic welding stations, and cutting and pressing equipment, making them suitable for numerous industrial scenarios.

Safety Curtain Sensors, Photoelectric Sensors, Proximity Sensors, Mesauring Sesnors, LED Tower Light