Great things in business are never done by one person. They’re done by a team of people. We have that dynamic group of peoples

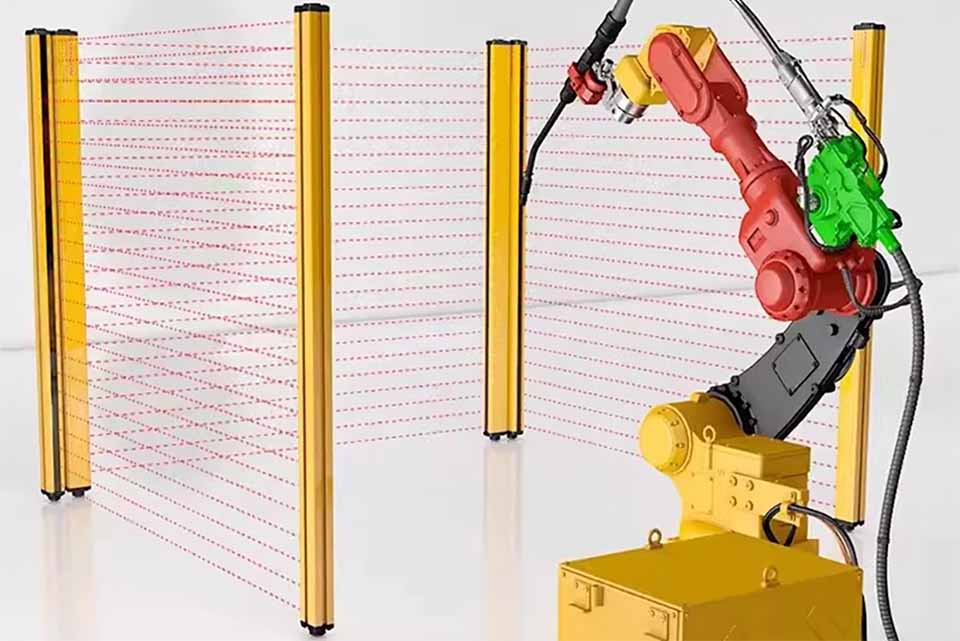

As the core protection device of modern industrial machinery, safety light curtain realizes real-time monitoring of dangerous areas of human-machine interaction through infrared light curtain technology. This paper systematically analyzes its technical principles, core functions and economic value in stamping equipment, and combines authoritative data and industry cases to reveal how safety light curtains can achieve the dual goals of “zero accident production” and “efficiency improvement”. Studies have shown that punching equipment equipped with safety light curtains can reduce the risk of work-related injuries by 89% and increase production efficiency by 15%-20%.

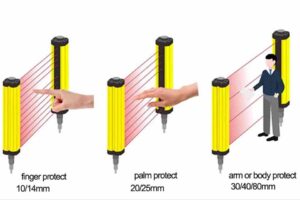

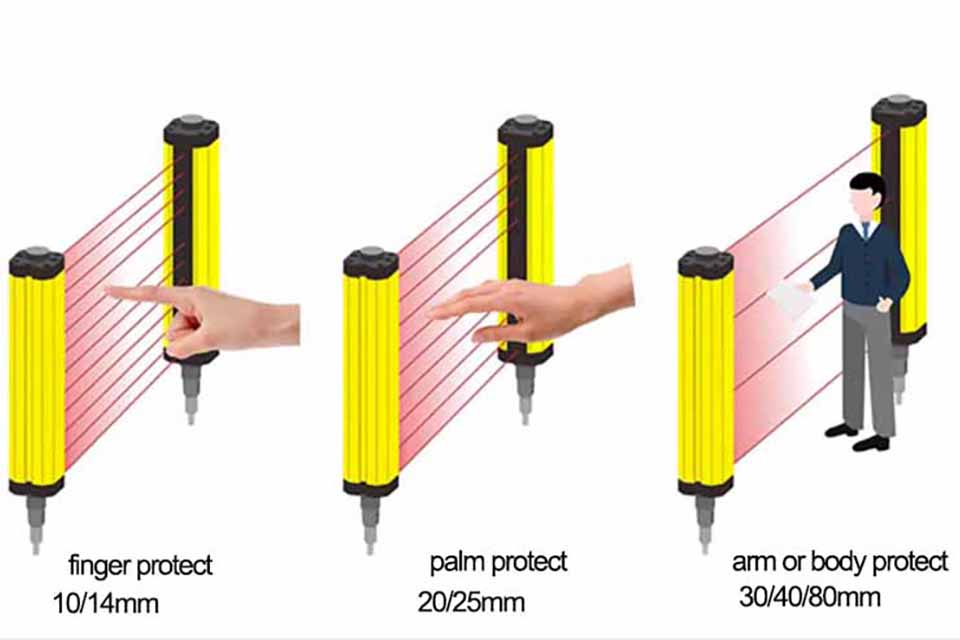

Safety light curtain adopts the third-generation digital light curtain technology to construct a three-dimensional protection network through high-density infrared beams (usually 14-48 beams). Compared with traditional mechanical protective covers, its response speed is increased to 0.02 seconds (ISO 13855 standard), which can effectively intercept the operator’s limbs from entering the dangerous area.

| Component Type | Traditional Mechanical Guards | Safety Light Curtain System |

|---|---|---|

| Response Time | 0.5-2 sec | 0.02 sec |

| Protection Coverage | Fixed area | Programmable zones |

| False Alarm Rate | 15%-20% | <0.1% |

Modern safety light curtains integrate the “transmit-receive” basic unit and the intelligent controller to achieve a three-level protection strategy:

Warning stage: When a foreign object is detected entering the warning zone, an audible and visual alarm is triggered

Deceleration stage: The punch stroke speed is reduced to a safe threshold (usually ≤10mm/s)

Emergency stop phase: Completely cut off the power supply (EN 60947-5-3 standard)

Case study: After the stamping workshop of an automobile parts factory installed our company’s series of gratings:

Equipment utilization rate increased from 72% to 89%

Mold change time shortened by 40%

Annual work injury compensation reduced by $280,000

| Value Dimension | Technical Implementation | Economic Benefit |

|---|---|---|

| Accident Prevention | Three-stage emergency stop response system | 89% reduction in occupational injury costs (OSHA) |

| Efficiency Boost | Non-contact detection technology | 15% reduction in downtime |

| Regulatory Compliance | ISO 12100 safety standard compliance | Avoids $50,000 per violation penalty |

| Equipment Protection | Overload current protection module | 30% extended equipment lifespan |

| Smart Integration | Industry 4.0 data interface support | 20% increase in production line intelligence |

| Environmental Adaptability | IP67 protection rating | 85% lower maintenance costs |

| Space Optimization | Compact design (60mm minimal thickness) | 40% space saving in installation |

After adopting our safety light curtain, the Tesla factory achieved:

2000-ton stamping line zero accident operation record

Production rhythm increased to 12SPM (times/minute)

After the precision stamping workshop is equipped with our safety grating, it can achieve:

Safe production of 0.5mm micro components

The yield rate is increased to 99.98%

The safety grating has achieved a leapfrog development from passive protection to active prevention through technological innovation. While ensuring the safety of operators, it brings about the improvement of production efficiency and optimization of operating costs, making it an indispensable core component of modern intelligent manufacturing. With the in-depth development of Industry 4.0, intelligent safety gratings will continue to promote human-machine collaboration into a new stage.

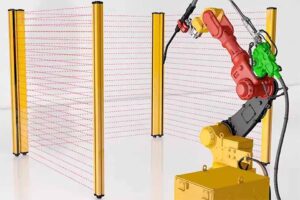

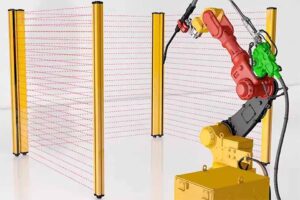

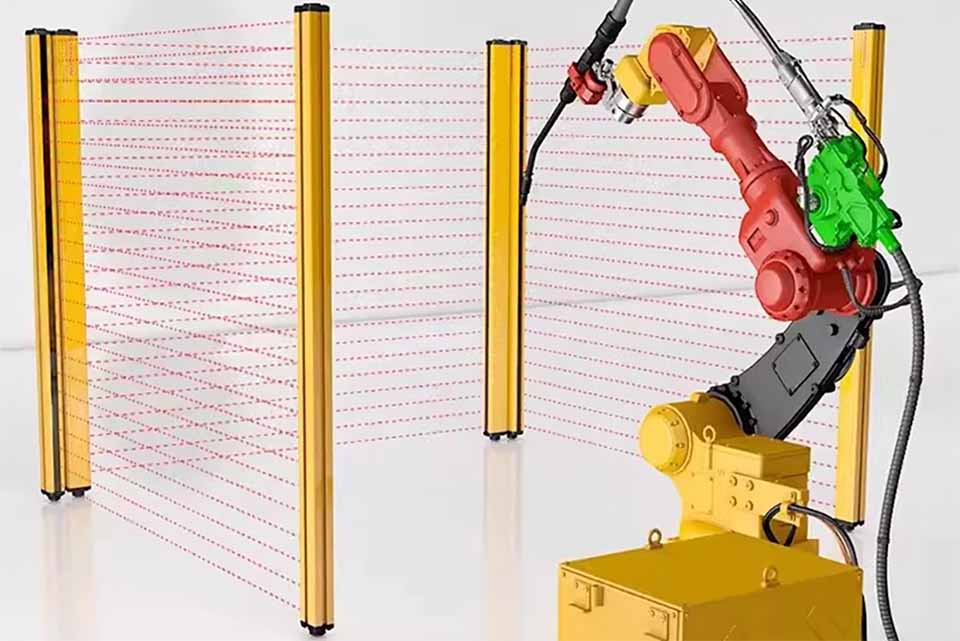

The safety curtains use an array of infrared light beams to create a safety barrier around dangerous machinery, ensuring that no one can accidentally enter a hazardous area without being detected.

Enhance your punching machine safety with our advanced safety light curtain sensor. Designed for optimal protection, it minimizes risks in industrial environments.

A picnic table is more than just a place to eat outdoors – it’s a centerpiece for creating lasting memories, hosting gatherings, and making the most of outdoor spaces.

A picnic table is more than just a place to eat outdoors – it’s a centerpiece for creating lasting memories, hosting gatherings, and making the most of outdoor spaces.

Enhance your punching machine safety with our advanced safety light curtain sensor. Designed for optimal protection, it minimizes risks in industrial environments.

A picnic table is more than just a place to eat outdoors – it’s a centerpiece for creating lasting memories, hosting gatherings, and making the most of outdoor spaces.

The safety curtains use an array of infrared light beams to create a safety barrier around dangerous machinery, ensuring that no one can accidentally enter a hazardous area without being detected.