Infrared Measuring Light Curtain Sensors For the Automotive Industry

Light curtain safety Sensors: core safety solution in the industrial automation

Technical principles, application advantages and selection guide

Basic principles: intelligent protection logic of infrared light curtain

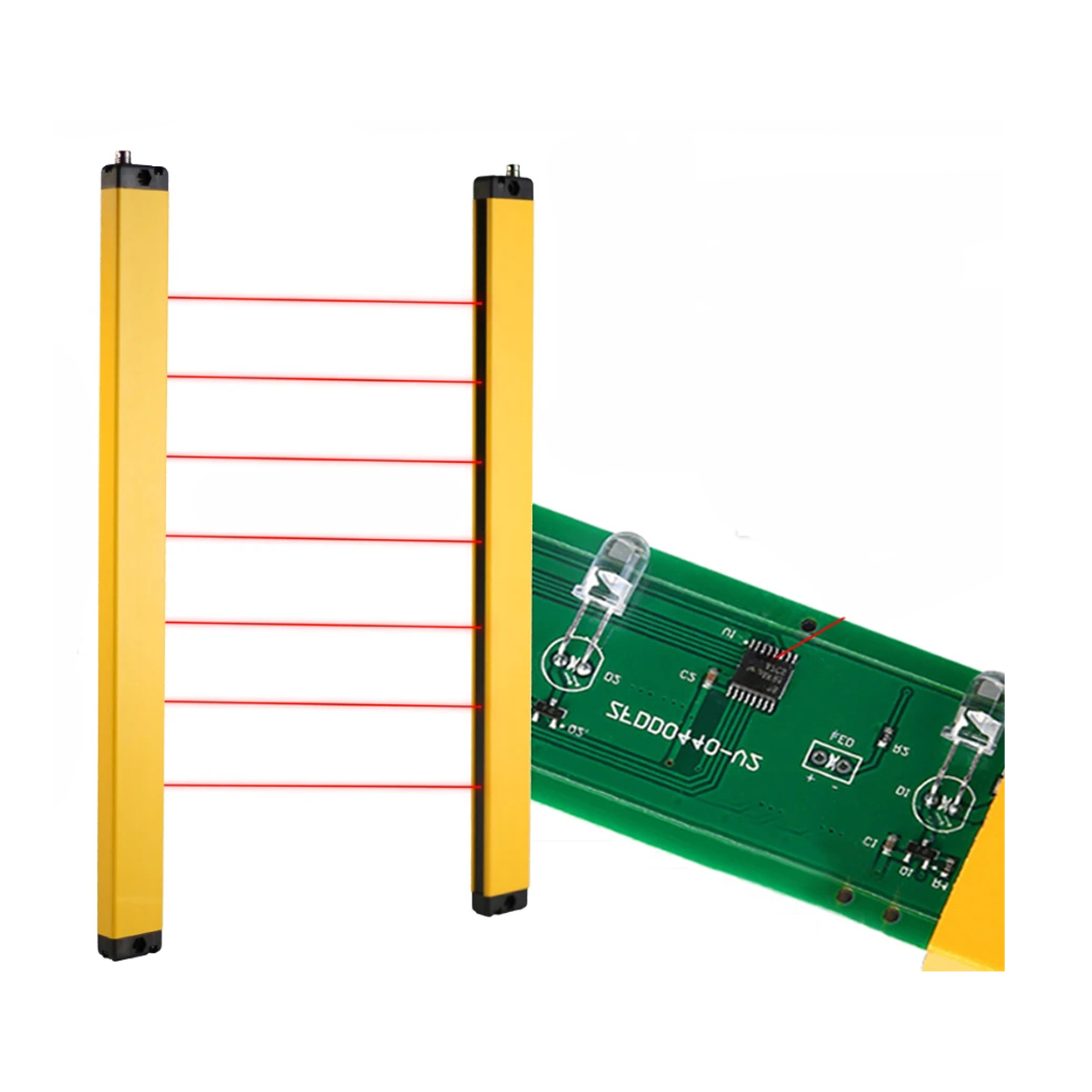

The light curtain sensors safety consists of a transmitter and a receiver, which forms a protection matrix by emitting infrared light beams. When an object invades the light curtain, the light path is blocked and a shutdown command is triggered, and the response time can reach microseconds. The latest technology integrates laser and visible light mixed light sources to increase the detection accuracy to ±1mm and support adaptive ambient light compensation.

Technology evolution: from single protection to intelligent

AI deep learning: Identify complex working conditions (such as steam and dust environments) through machine vision, and reduce false alarm rate by 40%

Edge computing integration: Localized data processing reduces network latency and supports real-time linkage with PLC/SCADA systems

Modular design: Supports rapid replacement of beam arrays to meet customized protection needs

Core application advantages in industrial scenarios

Safety performance upgrade

Comply with ISO 13849-1 safety standards and pass SIL3 certification

Form double protection with mechanical limit devices, and the accident rate is reduced by 65%

Support regional customized protection (such as 0.5-meter danger zone at the end of the robot arm)

Production efficiency empowerment

Non-contact design reduces equipment wear and reduces maintenance costs by 30%

Supports fast recovery mode, automatic reset after shutdown without manual intervention

Compatible with AGV/AMR navigation system to optimize warehouse logistics process

Full life cycle cost control

IP67 protection level adapts to harsh environment, with a service life of more than 8 years

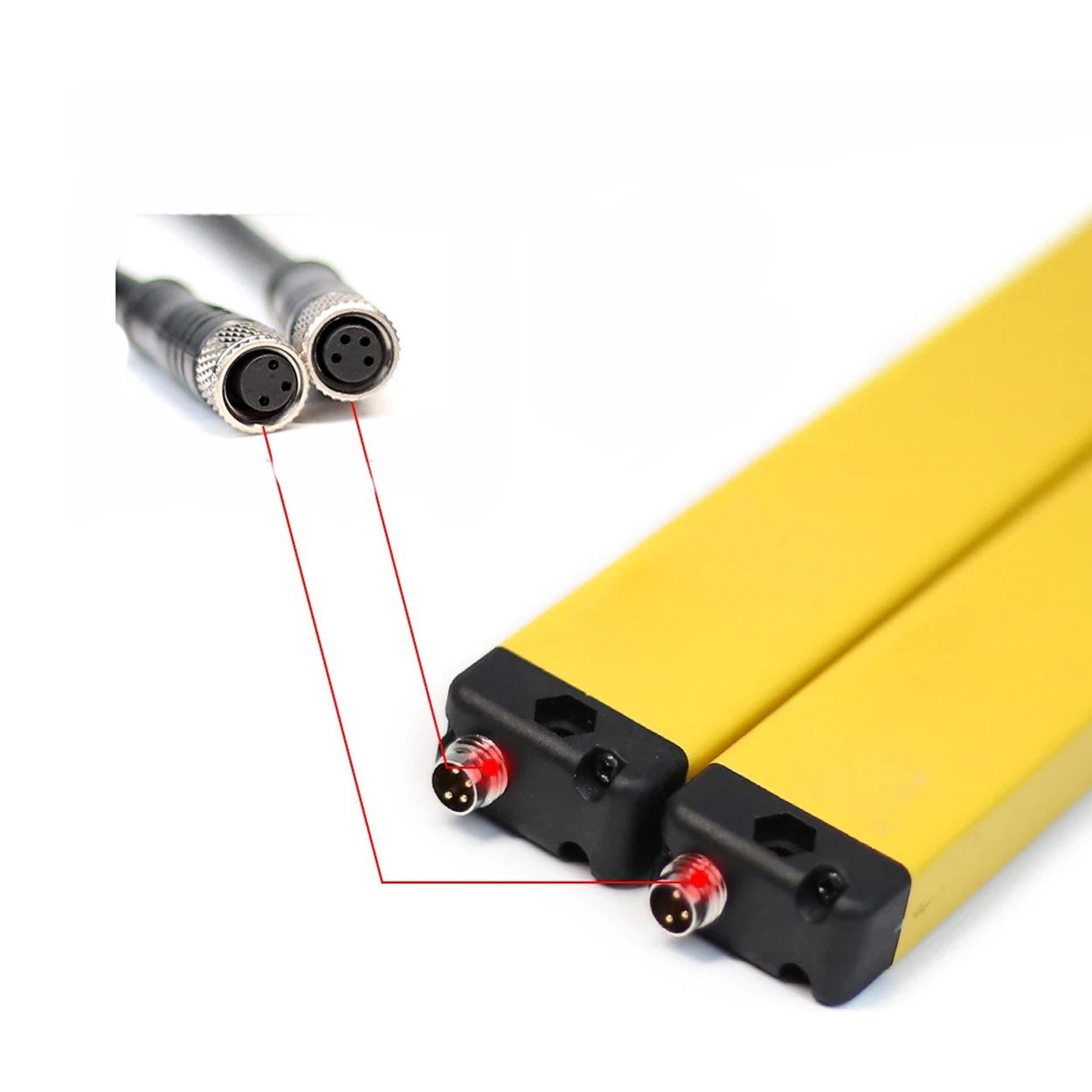

Standardized interface (such as Profinet/Modbus) reduces integration complexity

Provide remote diagnosis service, fault warning response time <15 minutes

Selection recommendations and implementation guide

Product Specifications

| Feature | Specification |

|---|---|

| Detection Range | Up to 10 meters (adjustable) |

| Beam Resolution | 20mm or 40mm (selectable) |

| Power Supply | 24V DC or 110-240V AC |

| Operating Temperature | -20°C to 55°C |

| Protection Rating | IP67 (dustproof and waterproof) |

| Compliance | ISO 13849, CE, RoHS |

| Response Time | < 20ms |

| Beam Configuration | 4, 8, or 16 beams |

| Mounting Options | Horizontal or vertical |

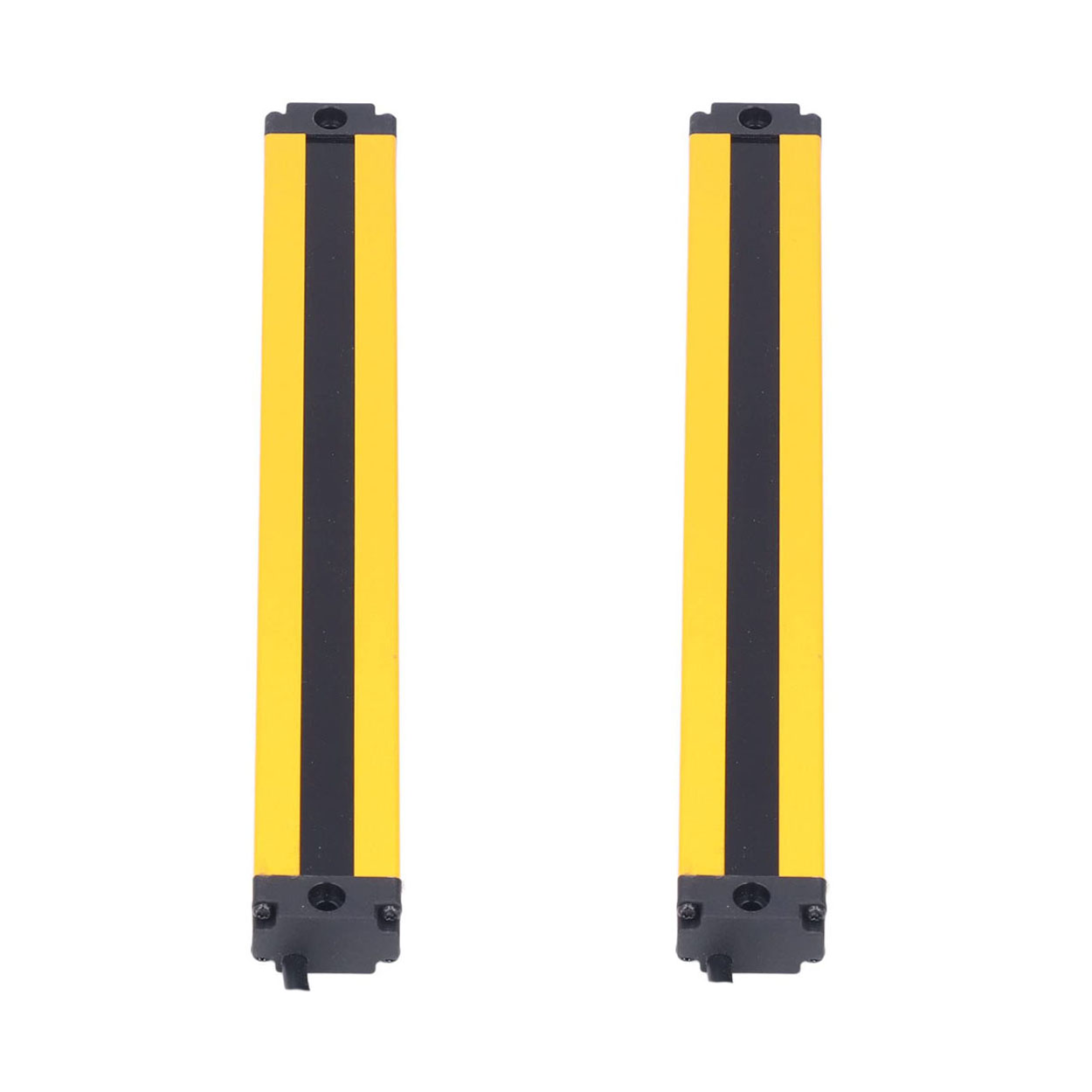

| Material | High-grade aluminum and polycarbonate |

| Dimensions | Varies by model |

| Weight | Lightweight design (e.g., 1.5kg) |

Integration and verification process

1. Use Google Lighthouse tool to detect page loading speed (target <3 seconds)

2. Monitor keyword rankings through Google Search Console (such as “industrial light curtain selection”)

3. Deploy A/B testing to compare the effects of different titles and descriptions

Future trends and industry insights

With the popularization of digital twin technology, light curtain safety gratings will achieve:

– **Virtual protection simulation**: Predict potential risks during system debugging

– **Multimodal perception fusion**: Combine sonar and pressure sensors to build a three-dimensional protection network

– **Edge computing and 5G collaboration**: Support industrial Internet of Things with concurrent access of millions of devices

Conclusion

With over 15 years of experience in manufacturing, we are proud to be among the top five safety curtain sensor manufacturers worldwide. Our commitment to innovation ensures that every sensor meets the highest quality standards, offering our clients the peace of mind they deserve.

Upgrade your safety systems today with the Body Protect Infrared Light Curtain Smart Safety Door Sensor, and experience the future of automation and safety.

Setting the Interception Distance

The interception distance, also known as the protective length, defines the maximum distance at which the receiver can effectively capture signals from the emitter. Proper configuration of this distance is essential for maintaining the sensor’s accuracy and responsiveness.

Performance and Reliability

Rapid Response Time

With a lightning-fast response time of 0.01 seconds, the Micoguard Light Curtain ensures immediate detection of any intrusions. The extensive detection range of up to 5 meters between the transmitter and receiver allows for comprehensive monitoring of large industrial spaces.

Stable and Interference-Resistant Output

The sensor operates independently of synchronization lines by utilizing a separate power supply. This design makes it highly resistant to electromagnetic interference, ensuring a stable and reliable output even in electrically noisy environments.

Quality and Durability

The Micoguard Light Curtain boasts a high-brightness indicator light, facilitating easy identification of its operational status. The surface treatment with high-quality baking varnish renders the sensor waterproof, oil-proof, and well-sealed, making it suitable for various demanding working environments.

Wide Range of Applications

This versatile safety light curtain is applicable in numerous industrial settings, including:

- Machine tool operation areas

- Production lines

- Automatic welding lines

- Automated equipment

- Cutting and pressing machinery

Its high protection grade (IP65) ensures optimal performance across different environments, enhancing workplace safety and operational continuity.

Conclusion

The Micoguard Light Curtain Safety Distance Laser Barrier Sensor stands out as a reliable and efficient solution for industrial safety. Its robust design, advanced self-diagnostic capabilities, and versatile application range make it an indispensable tool for protecting workers and ensuring the safe operation of machinery. By adhering to precise selection guidelines and leveraging its superior performance features, industries can significantly reduce work-related injuries and maintain a secure working environment.

Why Choose Us

Safe Light Guard

Our Safety Light Curtains represent a significant advancement in protective safety technology. With their robust construction, fast response times, and compliance with international safety standards, these sensors provide a critical safety function in various industrial settings. By integrating these systems, businesses can enhance operational safety and protect their most valuable assets— their people and their machinery.

Industrial Safety Upgrade

Incorporating safety light curtain sensors into industrial operations not only complies with legal safety standards but also promotes a culture of safety and responsibility. This technology is a cornerstone in modern industrial safety practices, playing a pivotal role in preventing accidents and enhancing overall workplace safety.

Frequently Asked Question

Know what you want to know about the barrier curtain sensors.

- These sensors are engineered for high-speed detection, responding to interruptions in as little as 0.01 seconds to ensure immediate protective measures.

Yes. With a rugged IP65 enclosure rating and high-quality surface treatments, the sensors resist dust, water, and oil, ensuring reliable operation in demanding environments..

- No. The sensors utilize optical synchronization technology (in integrated models), eliminating the need for hard-wired synchronization lines. This reduces installation complexity and maintenance requirements.

- Yes. The machine test signal function allows you to perform regular diagnostics on the safety system without disrupting normal operations, ensuring continuous safety compliance.

- The sensors can detect objects up to 5 meters away, offering adequate coverage and advanced warning in a variety of industrial setups.

- Absolutely. The sensors offer external device monitoring, allowing seamless integration with other safety components to form a comprehensive protective network.

- Beam coding minimizes false alarms by uniquely identifying and authenticating the signal beams. This ensures that the sensor only responds to genuine interruptions, improving overall detection accuracy.

- They are highly versatile and can be applied across diverse applications, including machine tool operations, production lines, automatic welding stations, and cutting and pressing equipment, making them suitable for numerous industrial scenarios.

Safety Curtain Sensors, Photoelectric Sensors, Proximity Sensors, Mesauring Sesnors, LED Tower Light