Infared Safety Light Barrier Curtain Manufacturer for Industry

Understanding the Role of Safety Light Curtains in Industrial Automation

Safety light curtains, particularly those classified as Type 4, are pivotal in safeguarding personnel and machinery in industrial environments. These advanced presence-sensing devices offer essential protection by creating an invisible barrier that detects any interruption in the flow of infrared beams. This interruption triggers an immediate response from the system, halting the operation of machinery to prevent potential accidents. On the other hand, Type 2 safety light curtains offer a more cost-effective solution for less hazardous applications, where the consequences of a safety breach are minimal. In this article, we explore the different categories, applications, and technical aspects of light curtains, emphasizing their growing importance in industrial safety.

What Are Safety Light Curtains?

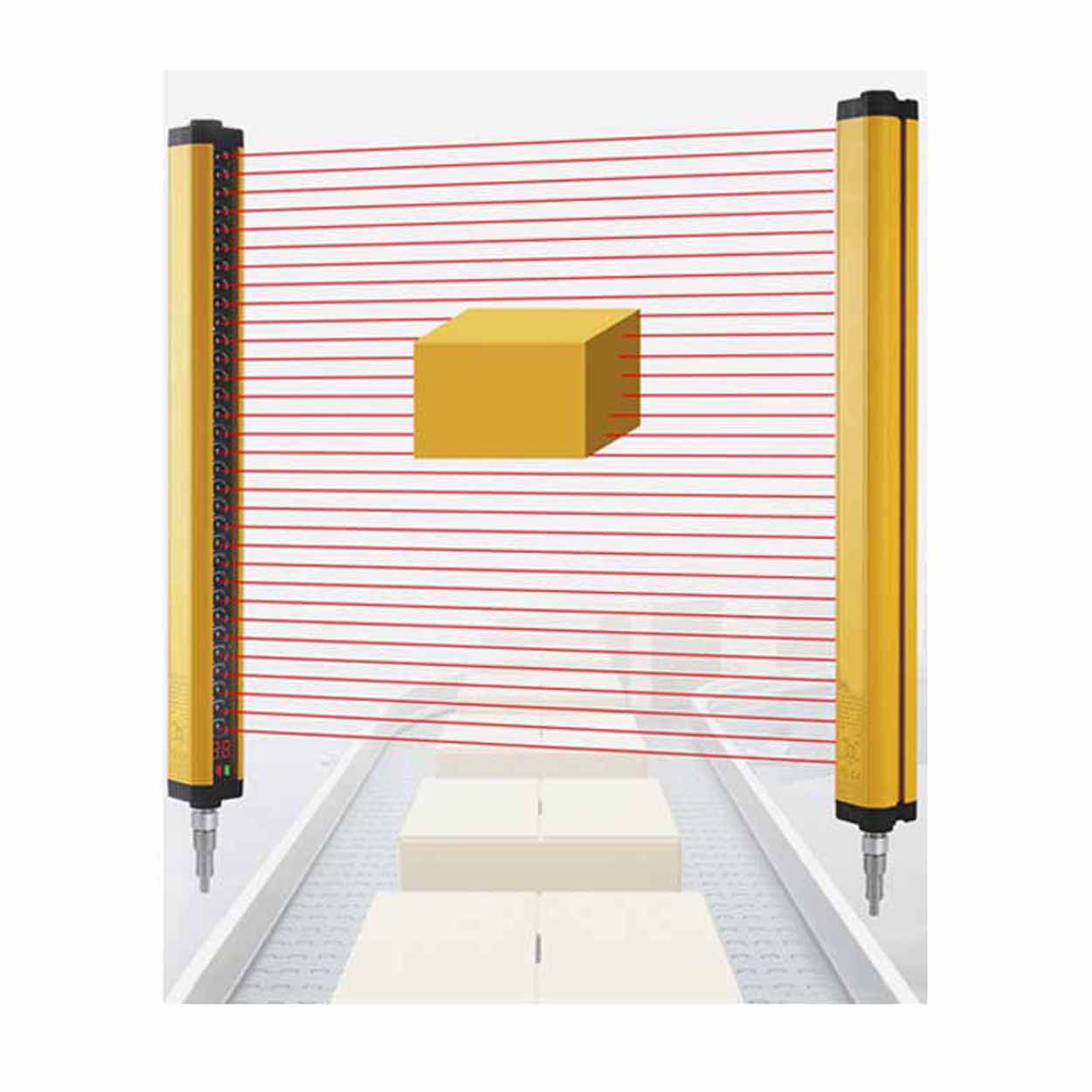

- Safety light curtains are non-contact protective devices designed to prevent injuries and damage in hazardous industrial environments. They consist of two primary components: an emitter and a receiver. The emitter sends out infrared beams, which are received by the receiver on the opposite side. If any object or person crosses these beams, the interruption signals the system to stop machinery, ensuring that operators are kept safe from moving parts, pinch points, or crushing hazards.

Types of Safety Light Curtains

Type 4 Safety Light Curtains

- Type 4 safety light curtains are the highest standard in industrial safety. These devices provide a high level of protection, specifically designed to detect human presence and prevent injuries in critical machine access areas. They are often deployed in high-risk environments where the potential for serious injury is significant.

Type 2 Safety Light Curtains

- Type 2 light curtains, by contrast, are ideal for less dangerous scenarios. These systems offer a more economical solution for applications where the risks of injury are lower and typically result in only minor harm. Although their protective capabilities are not as advanced as Type 4 systems, Type 2 light curtains are still highly effective in less hazardous contexts.

How Safety Light Curtains Operate

- Safety light curtains operate by emitting infrared beams that form an invisible barrier across a hazardous area. These beams, spaced at precise intervals, are designed to detect the presence of a person or object. Upon interruption of these beams, the system responds by triggering a machine stop command. This non-contact mechanism not only enhances safety but also prolongs the lifespan of equipment since there is no physical wear and tear on the light curtain, unlike mechanical safety switches.

Applications of Light Curtains in Industry

Safety light curtains are widely used in industrial settings for a variety of functions, particularly for:

- Guarding Against Moving Parts: Protecting operators from injury by ensuring they are kept clear of hazardous moving machinery.

- Pinching or Crushing Hazards: Preventing accidents where body parts could become caught in dangerous machinery.

- Personnel Access Control: Managing who can access specific areas to avoid accidental exposure to risks.

- Packaging and Sorting Lines: Ensuring safety around automated lines by controlling worker access to potentially hazardous sections.

- Maintenance Protection: Disabling machine startup while maintenance is underway, preventing accidents during repairs or adjustments.

These applications help reduce the risk of injuries and increase operational efficiency by ensuring safety without requiring physical barriers that take up valuable floor space.

Light Curtains vs. Safety Light Grids

While both safety light curtains and safety light grids utilize similar emitter-receiver systems, their design and applications vary. Safety light grids, typically used for long-range perimeter guarding, are equipped with fewer beams spaced farther apart. They offer lower resolution compared to light curtains and are best suited for large-scale applications where precise detection is less critical.

Key Differences Between Light Curtains and Safety Light Grids

Feature Safety Light Curtains Safety Light Grids Beam Resolution High (multiple beams) Low (few beams) Coverage Range Up to 20 meters Up to 60 meters Typical Applications Machine guarding, body protection Perimeter guarding Floor Space Requirement Smaller (compact) Larger (extended)

Advantages of Safety Light Curtains

Safety light curtains offer several significant advantages over mechanical safety solutions:

- Non-Contact Protection: Unlike door switches or mechanical guards, light curtains do not wear out from repeated use, resulting in a longer lifespan.

- Space Efficiency: Without the need for physical doors or barriers, light curtains save valuable floor space and offer more flexibility in the design of work areas.

- Enhanced Safety: By preventing physical contact, light curtains offer a higher level of protection for operators, reducing the risk of injury from machinery.

Technological Advancements in Light Curtain Design

Recent innovations in light curtain technology have led to the development of models that can monitor larger areas with greater precision. Some advanced systems now offer integration with machine control systems, allowing for automated responses based on detected movements. These improvements make safety light curtains an even more indispensable component of modern industrial automation, providing better reliability and more robust safety features.

Conclusion

he role of safety light curtains in industrial environments cannot be overstated. Whether used for high-risk access guarding or cost-effective perimeter protection, these devices provide essential protection for both personnel and machinery. Their non-contact design, durability, and ability to cover varying distances make them an invaluable safety solution across numerous industries. As technology continues to evolve, the capabilities of light curtains are expected to expand, further enhancing their effectiveness in safeguarding human workers and maintaining the smooth operation of industrial machinery.

Why Choose Us

Safe Light Guard

Our Safety Light Curtains represent a significant advancement in protective safety technology. With their robust construction, fast response times, and compliance with international safety standards, these sensors provide a critical safety function in various industrial settings. By integrating these systems, businesses can enhance operational safety and protect their most valuable assets— their people and their machinery.

Industrial Safety Upgrade

Incorporating safety light curtain sensors into industrial operations not only complies with legal safety standards but also promotes a culture of safety and responsibility. This technology is a cornerstone in modern industrial safety practices, playing a pivotal role in preventing accidents and enhancing overall workplace safety.

Frequently Asked Question

Know what you want to know about the safety curtain sensors

- Safety light curtains are optoelectronic devices that create an invisible barrier using beams of light, designed to detect and respond to any interruptions by stopping connected machinery, thereby preventing injuries and damage.

- Type 2 safety light curtains are used in lower-risk environments where any injury incurred might be minor, whereas Type 4 curtains are designed for high-risk areas where severe injury or death is possible.

- They are commonly used in industrial settings such as manufacturing plants, robot cells, automated production lines, and places handling hazardous materials.

Yes, there are specific models of safety light curtains that come with protective tubes and high protection ratings suitable for the stringent conditions in food and beverage manufacturing.

- They work by emitting beams of light from a transmitter to a receiver. If these beams are interrupted by any object or person, the machinery connected to the light curtain system is automatically shut down to prevent harm.

- Yes, safety light curtains come in various sizes to accommodate different safeguarding needs, from smaller machines to large hazardous areas.

- The choice depends on the specific safety requirements of your operation, the level of risk involved, and the area that needs to be safeguarded. Consulting with a safety expert or manufacturer can help determine the most suitable type.

Yes, they can be integrated with other safety and control systems to enhance overall plant safety and operational efficiency. This integration allows for a coordinated response to safety incidents, further minimizing risk.

Safety Curtain Sensors, Photoelectric Sensors, Proximity Sensors, Mesauring Sesnors, LED Tower Light